Understanding the Role of SMT Pick and Place Machines in Modern Electronics Manufacturing

Understanding automated component placement in SMT and its impact on PCB assembly

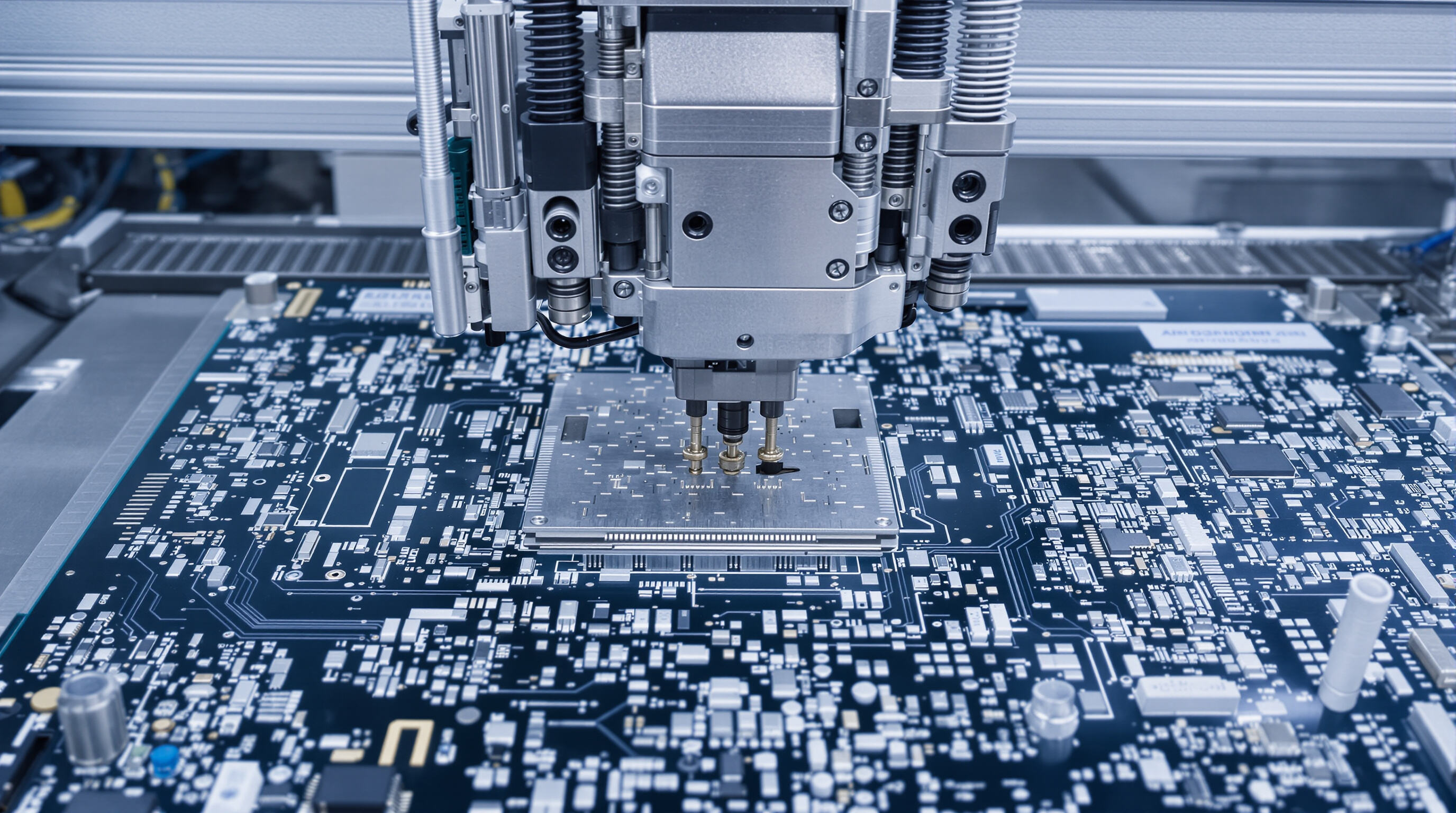

The introduction of automated component placement via Surface Mount Technology (SMT) changed how PCBs get assembled, making it possible to mount electronic parts with incredible precision down to the micron level. Manual assembly just can't compete anymore since SMT pick and place machines handle tiny components such as resistors and integrated circuits, some so small they're barely bigger than sand particles, and deposit them on circuit boards at speeds that would make anyone's head spin. The result? Far fewer mistakes from human hands, around 80 something percent fewer soldering issues according to industry reports, and the ability to create intricate circuit layouts that were simply not feasible before when space was at a premium in electronic devices.

How high-speed SMT pick and place machines enhance production efficiency

Modern high-speed SMT systems place 25,000–50,000 components per hour, accelerating assembly lines far beyond manual capabilities. With simultaneous multi-component pickup and intelligent feeder coordination, these machines cut production cycle times by 30–50% while maintaining ±0.025mm placement accuracy. Such efficiency directly translates to faster time-to-market for products from smartphones to medical devices.

The evolution of SMT technology in industrial applications

Surface Mount Technology (SMT) started out pretty simple back in the 1980s with just basic automation, but it's come a long way to where we have these smart AI systems today. Modern day SMT pick and place machines now feature advanced machine vision capabilities along with self-calibrating features that actually adjust on the fly when they detect tiny differences in components as they work. The improvements made over time are really important for making reliable electronic parts used in cars, planes, and all sorts of connected devices. These industries can't afford many mistakes at all, sometimes needing less than one defective part per thousand produced even when conditions get tough on factory floors.

Key Features That Define High-Performance SMT Pick and Place Systems

Precision in Electronics Manufacturing: Achieving Micron-Level Accuracy

Today's surface mount technology pick and place machines can position components within about 25 microns of their target location, which makes all the difference when dealing with those tiny 01005 packages measuring just 0.4 by 0.2 millimeters or integrated circuits with only 0.3mm between pins. These systems rely on high resolution servos combined with feedback loops to keep everything aligned even at speeds exceeding fifty thousand placements per hour. According to industry data from the latest electronics assembly benchmarks released in 2024, factories using these advanced systems typically see first pass yield rates pushing past 99.2%. For companies producing moderate volumes of boards packed densely with components, such accuracy translates into real money saved. Some manufacturers report cutting monthly rework expenses by nearly eighteen thousand dollars simply by upgrading their placement equipment.

Advanced Vision Systems and Real-Time Alignment for Reliable Component Placement

Modern multi-spectral machine vision systems can spot and fix placement errors in under 15 milliseconds. They use advanced 3D tomography techniques to get really detailed inspections down to about 15 microns resolution. What's impressive is how these systems handle real world problems automatically. For instance, they adjust for PCB boards that warp up to plus or minus 0.2 millimeters, something that plagues many manufacturers. They also correct feeder offsets during production runs. According to the latest data from the SMT Industry Report in 2023, this results in around 42 percent fewer placement defects compared with older single camera systems. One major equipment manufacturer saw remarkable improvements too. After switching to a hybrid approach combining laser and vision alignment technologies, their accuracy rate jumped to an impressive 98.6 percent when working with those tiny 0.25mm pitch connectors that are so challenging to place correctly.

Integration of AI and Predictive Analytics in SMT Pick and Place Systems

Self-learning algorithms analyze 120+ production variables—including nozzle wear rates and adhesive cure times—to optimize machine parameters. Facilities using AI-driven systems achieve 37% faster changeovers and 29% fewer nozzle jams (2024 Smart Manufacturing Data). Predictive maintenance modules forecast motor failures 400 hours in advance, cutting unplanned downtime by 68% in automotive electronics applications.

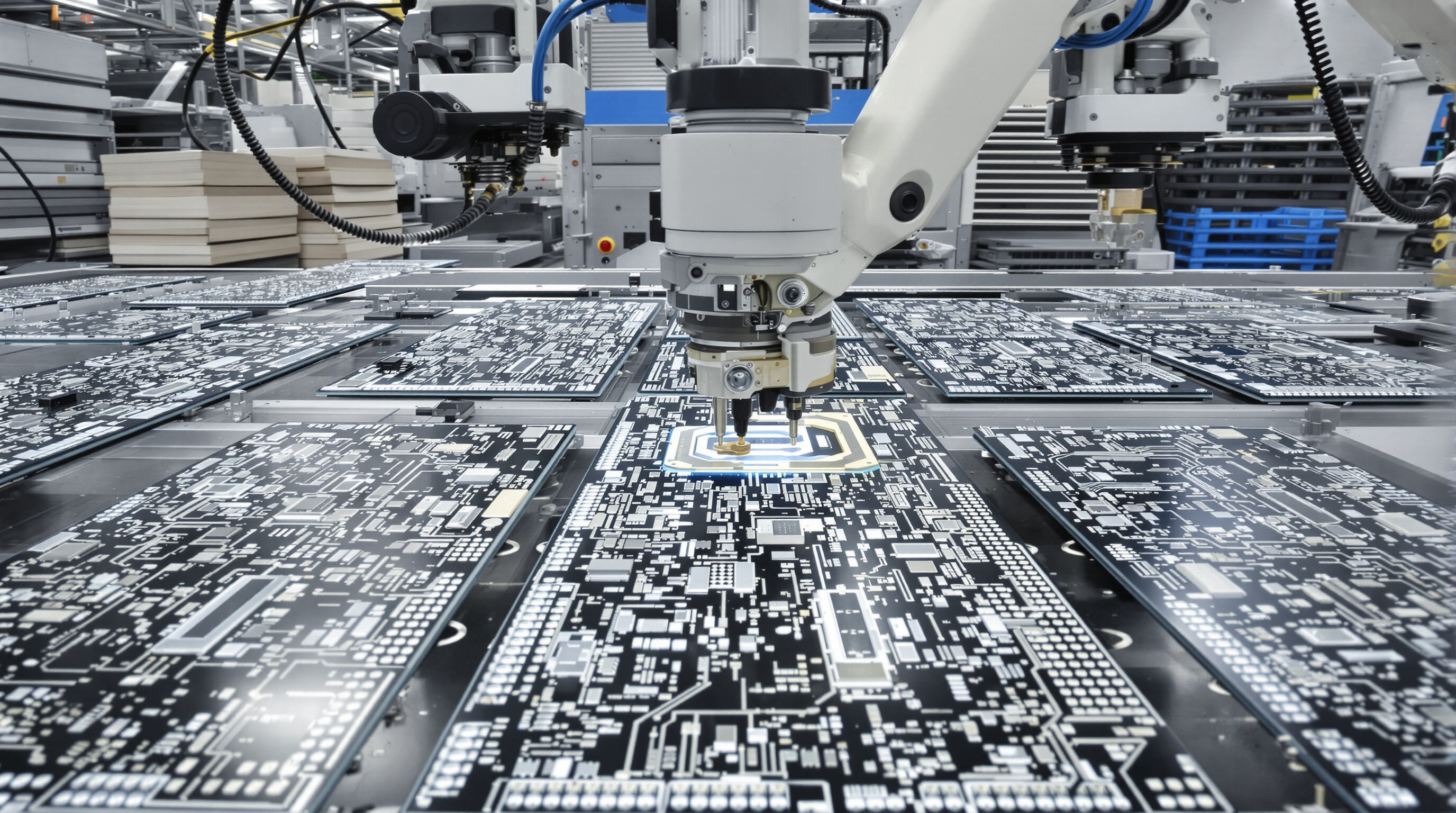

Scalability and Flexibility in Handling Diverse Component Types and PCB Layouts

The modular feeder racks can handle both 0402 capacitors measuring just 1 by 0.5 millimeters and those larger 45 by 45 millimeter QFN components all at once, and they do this without needing anyone to step in manually. Some tests ran on dual lane production lines found that these systems hit about 87 percent utilization even when moving back and forth between complex 12 layer server boards and those tricky flexible LED array setups according to what was published in last year's High Mix Manufacturing Review. And here's another plus point: replacing feeders doesn't require any tools whatsoever. This means getting the whole production line set up again takes under 22 minutes total time, which beats older equipment by roughly two thirds according to industry benchmarks.

Maximizing Production Throughput with Automated SMT Placement

Measuring Throughput and Production Efficiency Gains in Real-World SMT Lines

The latest surface mount technology pick and place machines can handle over 25 thousand parts each hour during actual production runs, while top tier models manage to keep mistakes down to under five defects out of every million placements. According to research published in early 2024 looking at seventy eight different electronic manufacturing sites across North America and Europe, companies that upgraded to these advanced placement systems saw a significant boost in their utilization productivity rates, clocking in around thirty two percent improvement compared to previous years. This kind of efficiency translates into real world benefits too, as product development cycles get shorter and manufacturers can bring those complicated printed circuit board designs to market much quicker than before.

Case Study: 40% Output Increase After Upgrading to High-Speed Component Placement

One mid sized auto parts maker saw their output jump around 40 percent after installing a modular surface mount technology system that handles two lanes at once. With this new setup, they can place those tiny 0201 components measuring just 0.2 by 0.1 millimeters alongside larger 15 by 15 mm QFN packages all in one go, and still manage to keep first pass yields hovering near 99%. What really stands out is how this combination method cuts out all the manual work needed when dealing with different board technologies. Changeovers that used to take almost an hour now wrap up in less than ten minutes per batch, which makes a huge difference in day to day operations.

Reducing Cycle Times Through Optimized Feeder Configurations and Placement Algorithms

Today's surface mount technology (SMT) production lines are getting smarter thanks to artificial intelligence systems that optimize feeder setups. These smart systems analyze the layout of printed circuit boards in real time, coordinate when materials arrive at the workstation, and constantly adjust the path the machine takes between components. The results speak for themselves: machines now travel shorter distances between parts, cutting down on wasted movement by around 20%. Pick and place operations happen incredibly fast too, often under 0.08 seconds for each individual component. Even at full speed, these advanced systems can still place components within about 25 micrometers of their target location. This level of precision is made possible through special gantry designs that absorb vibrations during operation, ensuring consistent quality across all manufactured boards.

Evaluating the Long-Term Value of Investing in Pro-Grade SMT Equipment

Total cost of ownership vs. short-term savings in selecting the right smt pick and place machine

While professional SMT pick and place machines cost more upfront, they actually offer better value over time. Looking at total cost of ownership tells a different story than what cheaper options promise. Budget machines require constant recalibration, produce more defects, and eat up electricity faster than their pricier counterparts. These hidden costs really add up in the long run. Industrial grade systems keep placing components accurately even after hundreds of thousands of cycles, with hardly any downtime to speak of. Many manufacturers find that these machines cut down on costs per assembled board by around 30% within about three years of operation. Real world examples from factories across the country consistently point to payback periods somewhere between 18 and 24 months just from improved production speed alone.

Depreciation, maintenance, and upgrade paths for advanced SMT placement systems

The modular design of industrial systems helps them maintain better residual value since components can be upgraded individually over time. Maintenance teams now use predictive protocols with built-in sensors that spot signs of component wear long before actual failures happen. Most manufacturers follow technology roadmaps that keep their equipment compatible with new packaging standards via regular software updates, which often means these machines stay relevant for well over eight years in many cases. When companies optimize their maintenance schedules properly, they typically see around a 50% reduction in unexpected downtime, and this approach definitely helps preserve the overall value of their assets throughout their operational life.

Industry demand driving resale value and ROI for high-performance SMT machines

The SMT equipment market, now valued at around $13.6 billion, keeps creating solid opportunities in the used equipment sector for high precision machines. Equipment capable of maintaining measurements down to the micron level tends to hold their value well in the resale market, often fetching back between half to three quarters of what was originally paid after five years on the factory floor. Some companies have even seen their return on investment hit 100% within just three years when factoring in reduced operating costs. What this means practically is that what used to be considered depreciating assets are increasingly becoming investments that actually gain value over time in many manufacturing settings.

FAQs

What is Surface Mount Technology (SMT) used for in electronics manufacturing?

Surface Mount Technology (SMT) is used for assembling electronic components onto printed circuit boards (PCBs) with precision and efficiency, replacing manual assembly for its superior accuracy and speed.

How does an SMT pick and place machine work?

An SMT pick and place machine automates the placement of tiny components onto a PCB by picking them from feeders and placing them onto the board with high precision, using advanced vision systems and alignment technologies.

Why is precision important in SMT pick and place systems?

Precision is important because it ensures accurate placement of components, reducing defects and improving the reliability of the electronic products being manufactured.

What are the benefits of investing in high-performance SMT machines?

High-performance SMT machines offer better accuracy, faster production times, reduced operational costs, and maintain value better over time compared to budget machines.

Table of Contents

- Understanding the Role of SMT Pick and Place Machines in Modern Electronics Manufacturing

-

Key Features That Define High-Performance SMT Pick and Place Systems

- Precision in Electronics Manufacturing: Achieving Micron-Level Accuracy

- Advanced Vision Systems and Real-Time Alignment for Reliable Component Placement

- Integration of AI and Predictive Analytics in SMT Pick and Place Systems

- Scalability and Flexibility in Handling Diverse Component Types and PCB Layouts

- Maximizing Production Throughput with Automated SMT Placement

- Evaluating the Long-Term Value of Investing in Pro-Grade SMT Equipment

- FAQs