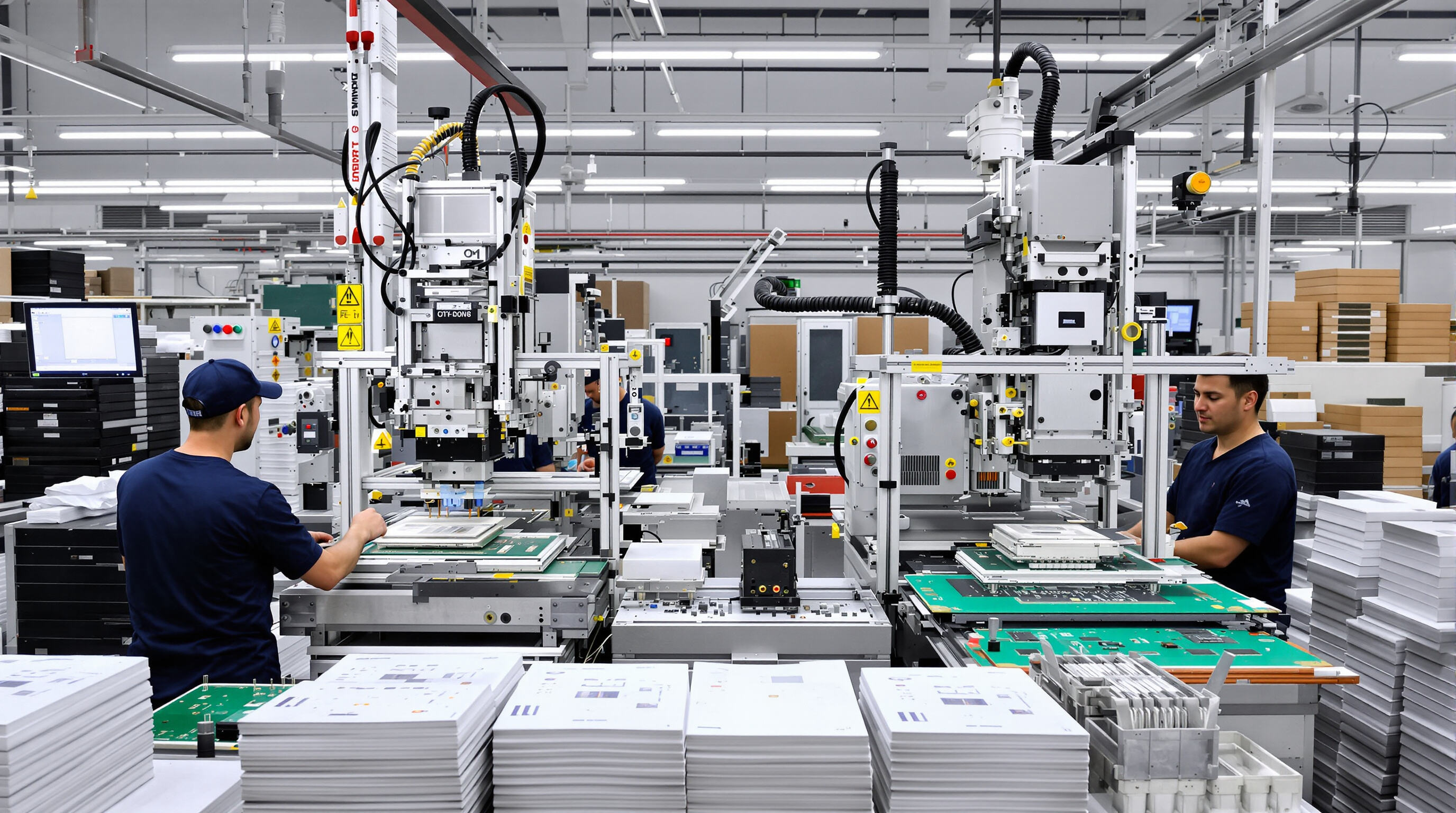

Choosing the Wrong SMT Pick and Place Machine Type for Your Production Needs

Understanding the difference between chip shooter and odd-form SMT pick and place machines

Chip shooter SMT machines excel at placing those tiny standard parts like resistors and capacitors really fast. Some models can crank out around 200k components an hour. But when it comes to weird shaped stuff, we need different equipment. Odd form machines deal with connectors, transformers, LEDs and other non-standard parts. They have special grippers and fancy vision systems to handle these tricky components. The downside? These machines run much slower, usually under 8k components per hour. A recent survey by IPC found that almost half (42%) of manufacturers ran into production problems when trying to force chip shooters to handle parts taller than 6mm. That shows why getting the right machine for the job matters so much in manufacturing.

Matching machine type to component mix and throughput requirements

Manufacturers tailor machine allocation based on product complexity. For example, smartphone producers dedicate 72% of their SMT equipment budget to chip shooters, while industrial control board lines allocate only 55% due to higher odd-form component usage. Use the following table to assess your production profile:

| Production Factor | Chip Shooter Focus | Odd-Form Focus |

|---|---|---|

| Standard Components | 85% | <15% |

| Average Board Complexity | <200 placements | 500 placements |

| Changeover Frequency | Low (<2/day) | High (5/day) |

Aligning machine capabilities with these factors ensures optimal throughput and minimizes bottlenecks.

Case study: Production bottleneck caused by incorrect machine selection

One medical device company ended up losing around $740,000 in revenue according to Ponemon's 2023 report when they installed three high speed chip shooting machines for circuit boards containing roughly 23% irregular shaped components. These particular machines had only an 8mm range of motion on the Z axis, which simply wasn't enough for the 12mm tall parts they needed to place. As a result, there were constant issues with component placement failures requiring lots of manual corrections later on. Throughput dropped by nearly two thirds because of all this, showing just how expensive it can be when manufacturers pick equipment that doesn't match their actual production needs.

Strategy: Conducting a component-by-component production audit before purchase

Top-tier manufacturers conduct a structured 4-phase audit before procurement:

- Document component heights, weights, and thermal profiles

- Map placement sequence conflicts (e.g., tall parts obstructing adjacent placements)

- Validate feeder compatibility across candidate machine models

- Test prototype boards with IPC 9850 compliance checks

This process uncovers 31% more critical requirements than basic spec comparisons (IPC 2023), ensuring machine capabilities align with real-world production demands.

Ignoring Feeder Compatibility and Configuration in SMT Pick and Place Machine Setup

Comparing Feeder Types: Tape, Tray, Tube, Vibratory, and Bulk Feeders

For those tiny chip components on carrier reels, tape feeders are still king of the hill, though they need pretty exact width matching within about 0.2mm to avoid getting stuck. When it comes to bigger stuff like BGAs, tray feeders work well enough but switching between them takes roughly 25% longer than other methods. Tube feeders handle those round parts nicely, think diodes and LEDs mostly. Vibratory feeders can get irregular shapes oriented properly too, although neither really holds up when running over 15 thousand pieces per hour without some sort of misalignment issues popping up. Bulk feeders are great for churning out massive quantities of resistors and capacitors, but forget about using them for anything as small as 0402 size components where precision matters most.

The Impact of Choosing the Wrong Type of Feeder (Push vs Drag, CL Feeders)

The push-style feeder relies on motorized sprockets to move the tape along, but there's always that annoying 0.3 second delay each time it picks up components. This slowdown really hurts productivity when manufacturing large quantities of LEDs. Drag systems solve the timing problem, yet they tend to mishandle delicate connectors which can cause all sorts of issues down the line. Then we have closed loop feeders that give constant feedback about tape tension as it moves through the machine. According to an Intel study from last year, these systems cut down on waste materials by almost a third. Of course, they do need special software to run properly. And here's something manufacturers often overlook: using push feeders for smaller production runs actually leads to around 18% fewer good products because the pockets don't align correctly with the components being placed.

Common Mistake: Purchasing a Machine That Doesn’t Support Required Tape Widths

About 28% of electronics makers run into trouble when their SMT machines can't handle tapes wider than 12mm, something pretty common with power MOSFETs and various connectors. Take one manufacturer of automotive sensors who ended up losing around $740,000 according to a 2023 study by Ponemon Institute because they bought a new machine that only worked with 8mm feeders even though suppliers had promised otherwise. The bottom line? Double check if machines will actually work with the widest tapes needed, particularly important for industrial PCB applications where 24mm or larger tapes are often required. A simple verification step could save companies thousands down the road.

Best Practices for Optimizing Feeder Layout and Changeover Efficiency

| Strategy | Benefit | Implementation Time |

|---|---|---|

| Cluster feeds by placement frequency | Reduces robotic head travel 40% | 1-2 hours |

| Standardize tape widths per zone | Cuts changeovers by 30-50% | Pre-production |

| Use modular trolleys for NPI runs | Enables line reconfiguration in 15min | <1 week |

| Calibrate CL feeders monthly | Maintains ±0.05mm placement accuracy | Ongoing |

Overlooking Component Placement Accuracy and Machine Calibration

How component placement accuracy affects yield and rework rates

Misalignment during SMT placement directly impacts solder joint quality. Errors under 0.05mm can increase rework rates by up to 35%, leading to defects such as tombstoning, bridging, and skewed components. High placement accuracy is essential for maximizing first-pass yield and minimizing costly manual corrections.

The role of camera systems and head access in ensuring reachability and precision

Advanced vision systems use real-time optical calibration to correct positional deviations, while robotic head kinematics enable precise handling of fine-pitch components. Machines equipped with dual optical inspection and multi-angle head rotation achieve micron-level accuracy, even for 01005-size components at high speeds.

Machine calibration and factory testing issues leading to early failures

Inadequate factory calibration leads to premature operational issues. Thermal drift in linear guides alone contributes to $740k in annual downtime across the electronics sector (Ponemon 2023). Modern machines with integrated optical encoders and real-time compensation algorithms reduce calibration downtime by 70%, according to sensor integration research.

Strategy: Requiring on-site factory acceptance testing before final payment

Insist on Factory Acceptance Testing (FAT) with production-representative PCBs before final payment. On-site validation under real operating conditions uncovers calibration gaps and performance limitations not evident in controlled lab testsâ&128;&148;especially critical for flex circuits and high-rotation assemblies.

Underestimating Real-World Speed and CPH Performance of SMT Pick and Place Machines

Advertised vs Actual CPH: Why Specifications Can Be Misleading

Manufacturers often quote CPH rates based on ideal IPC 9850 test conditions using identical components, which rarely reflect mixed-production environments. A 2023 SMT benchmarking study found actual throughput falls 30â&128;&147;40% below advertised specs due to variables like nozzle changes, vision recalibrations, and component diversityâ&128;&147;such as combining 0201 resistors with QFPs and BGAs.

Factors Affecting Real-World Throughput: Placement Accuracy Trade-Offs, Feeder Delays

Three primary factors reduce real-world throughput:

- Speed vs precision balance: High-accuracy modes (±0.05mm) run 18â&128;&147;22% slower than maximum-speed modes (±0.1mm)

- Feeder replenishment lag: Manual tape refills cause 9â&128;&147;14 minutes of downtime per hour

- Component recognition delays: Mixed 2D/3D vision systems add 0.3â&128;&147;0.7 seconds per atypical component

These compounding inefficiencies are rarely reflected in manufacturer datasheets.

Case Study: Over-Purchasing Capacity Leading to Wasted Investment

A medical device company invested in an ultra-high-speed SMT machine rated at 53,000 CPH for a product requiring just 11,000 daily placements. The $287,000 premium for unused capacity could have funded a full optical inspection system. To avoid overbuying, calculate target CPH using:

(Peak daily placements × 1.2 safety factor) / (Operating hours × 60 × 60) = Target CPH Organizations using this formula achieve 93% machine utilization, compared to 61% for those relying solely on advertised specs.

Neglecting Software Integration, Usability, and Post-Purchase Support

Software integration issues with existing MES and production tracking systems

When companies bring in new SMT equipment without checking if it works with their current Manufacturing Execution Systems (MES), they end up creating those annoying data silos that mess with real time monitoring capabilities. According to some industry research from 2025, about 40 percent of all software deployments fail because people didn't get proper training on how to use them. Funny thing is, most of these training programs focus solely on teaching engineers while completely ignoring the operators who actually run the machines day to day. And let's not forget about those pesky API issues where new machinery doesn't talk properly to older systems. These kinds of problems make it really hard to track what's happening on the factory floor and keep accurate records throughout the production process.

User experience pitfalls: Clunky interfaces and non-intuitive programming

Complex programming interfaces increase board changeover time by 17%. Operators struggle with deeply nested menus and poorly organized placement rules, leading to misconfigured libraries and calibration errors. An intuitive UI reduces setup errors and accelerates operator proficiency.

Controversy analysis: Proprietary software locking customers into vendor ecosystems

Many vendors bundle hardware with proprietary software, locking customers into costly upgrade cycles. Such systems demand 30â&128;&147;50% higher licensing fees than open-platform alternatives and restrict third-party maintenance. This ecosystem dependency limits feeder and vision system flexibility, increasing long-term operational costs.

The hidden cost of poor technical support and long response times

Facilities with over three-hour support response times face 38% higher defect rates during outages, costing up to $35,000 per hour in high-volume lines. Legacy machine owners report six-week lead times for proprietary nozzles, while open-architecture systems enable 72-hour part delivery from multiple suppliers.

Questions to ask vendors about service availability and spare parts logistics

| Category | Key Verification Questions |

|---|---|

| Service Level Agreements | Do guarantees include onsite technician response within 8 business hours for urgent malfunctions? |

| Parts Availability | What critical components (vision cameras, servo motors) are stocked regionally? |

| Software Support | Is your software compatible with common XML/Gerber data formats from major CAD providers? |

| Long-Term Planning | What’s the roadmap for backward compatibility with next-gen hardware? |

FAQ

What is the difference between chip shooter and odd-form SMT machines?

Chip shooter SMT machines excel at placing tiny standard components at high speed, while odd-form SMT machines handle non-standard parts such as connectors and LEDs, though they operate at a slower pace.

Why is matching machine type to component mix important?

Matching the machine to component mix is crucial for optimizing throughput and minimizing production bottlenecks, as different machines cater to different component sizes and shapes.

How can incorrect machine selection impact production?

Incorrect machine selection can lead to production failures, increased manual corrections, and decreased throughput, resulting in financial losses for manufacturers.

What are the different types of feeders used in SMT machines?

SMT machines utilize various feeders such as tape, tray, tube, vibratory, and bulk feeders to handle components, each suited for specific shapes and production rates.

How can organizations avoid over-purchasing machine capacity?

Organizations can avoid over-purchasing machine capacity by calculating target CPH using daily placements and safety factors, ensuring efficient machine utilization.

What are the common software integration issues with SMT machines?

Common issues include incompatibility with existing MES and production tracking systems, leading to data silos, monitoring challenges, and failure rates in software deployment.

Table of Contents

-

Choosing the Wrong SMT Pick and Place Machine Type for Your Production Needs

- Understanding the difference between chip shooter and odd-form SMT pick and place machines

- Matching machine type to component mix and throughput requirements

- Case study: Production bottleneck caused by incorrect machine selection

- Strategy: Conducting a component-by-component production audit before purchase

- Ignoring Feeder Compatibility and Configuration in SMT Pick and Place Machine Setup

- Overlooking Component Placement Accuracy and Machine Calibration

- Underestimating Real-World Speed and CPH Performance of SMT Pick and Place Machines

- Neglecting Software Integration, Usability, and Post-Purchase Support

-

FAQ

- What is the difference between chip shooter and odd-form SMT machines?

- Why is matching machine type to component mix important?

- How can incorrect machine selection impact production?

- What are the different types of feeders used in SMT machines?

- How can organizations avoid over-purchasing machine capacity?

- What are the common software integration issues with SMT machines?