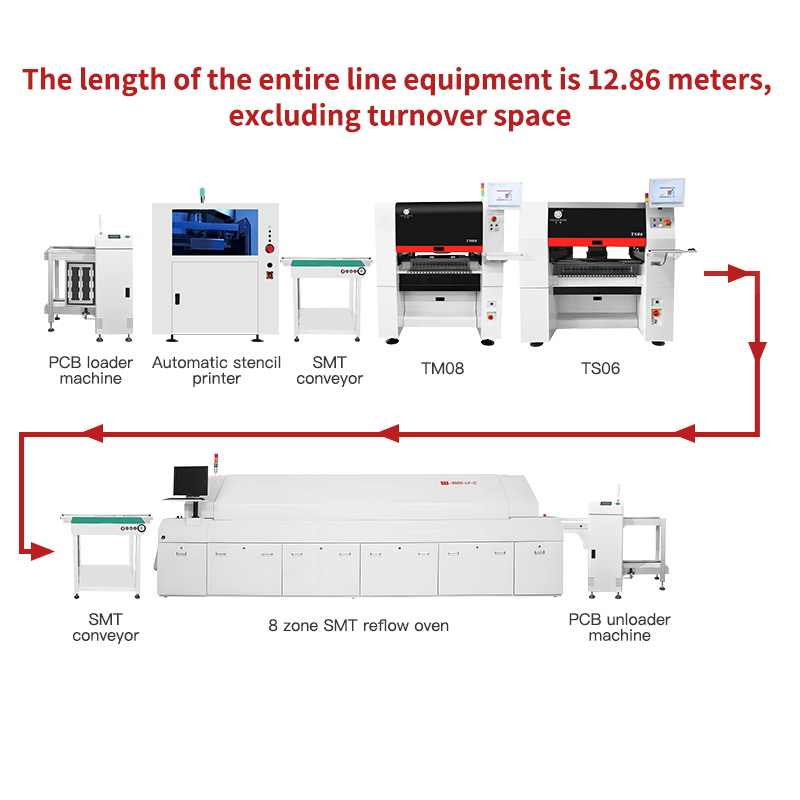

RS10 10 Head *2 Gantry Smd Pick and Place Assembly Machine

82000CPH, Dual-Gantry, dual-rail magnetic levitation drive for stable, accurate, and fast placement; a core piece of equipment for mass production.

- Overview

- Parameter

- Recommended Products

This model adopts the integrated structure of precision machinery and uses Charmhigh independent research and development results.

It has the characteristics of high precision, high stability, complete functions and convenient use.

Its optimal mounting speed is 82000CPH.

2. Machine features

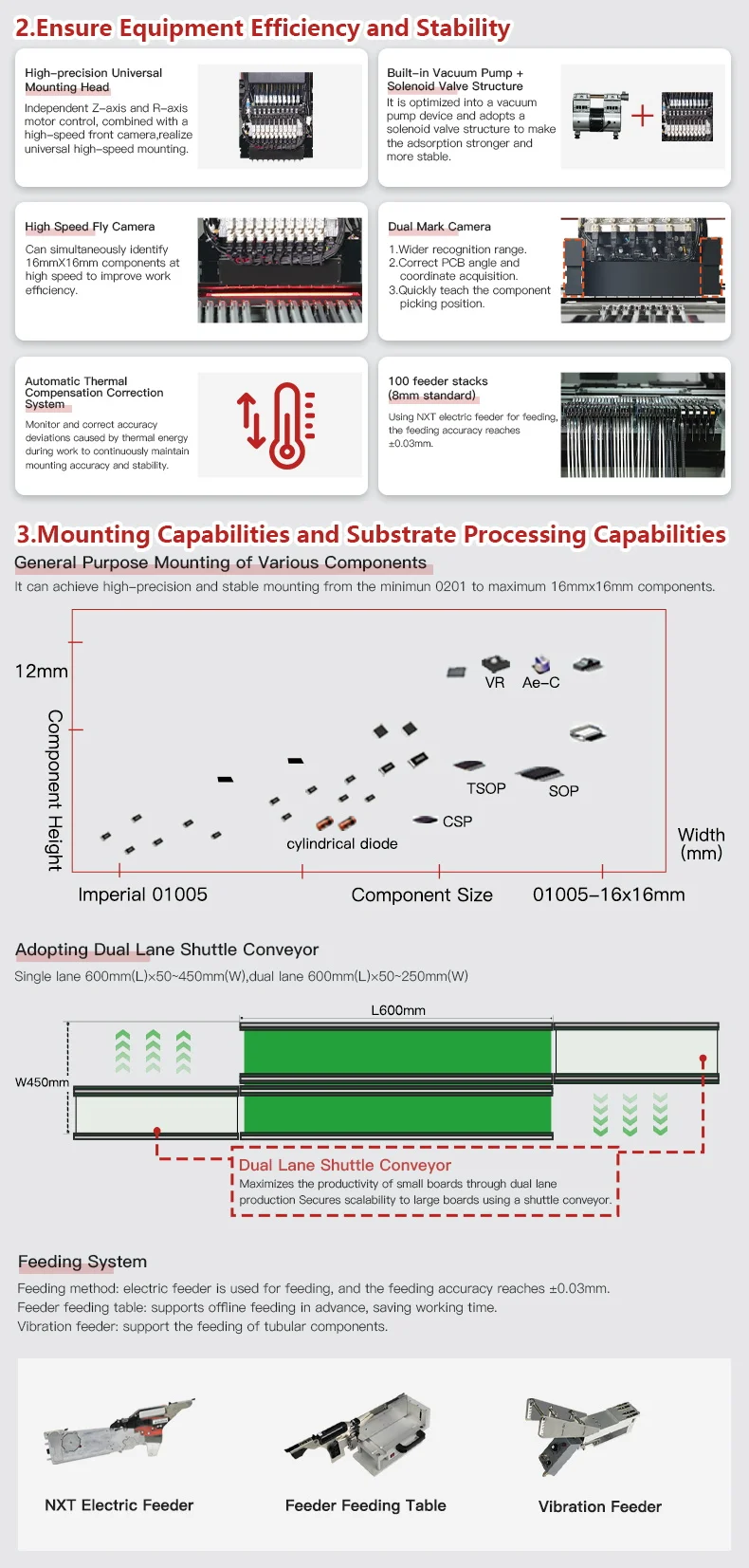

1. Thermal Compensation

2. Mounting Range:The minimum: 01005/maximum:16mm(L)×16mm(W)

3. Vacuum Pump

4. Automatic nozzle change(31 sets nozzle library)

5. Dual Lane Shuttle Conveyor

6. 10 head * 2 gantry(front and rear arms)

7. 100 NXT8mm feeder stacks

For more machine features, please consult our account manager

3. Parts List

Item |

Quantity |

Item |

Quantity |

RS20 Pick and Place Machine |

1 |

Vacuum Cotton |

20 |

Nozzles |

40 |

Aviation Plug |

2 |

Tool box |

1 |

Quick connector |

1 |

Warranty Card |

1 |

Thimble |

4 |

User Manual |

1 |

Mouse Pad |

1 |

Test Report |

1 |

Rubber Damping Pad |

4 |

Brush |

1 |

Power Cable |

1 |

Tweezer |

1 |

Keyboard |

1 |

Inner Hexagon Spanner |

1 |

mouse |

1 |

Open-ended Wrench |

2 |

LCD*1 |

1 |

Lubricating oil |

1 |

Product Parameters

|

RS20 Specifications |

|

|

Dimensions |

1400mm(L)×1890mm(W)×1550mm(H) |

|

Weight |

2500kg |

|

Power Supply |

AC380V (50Hz, three phase), 5kW |

|

Air Supply |

0.5MPa ~0.7MPa |

|

Vacuum Generation |

Built-in dual vacuum pump |

|

Mounting Head Quantity |

10 head*1 gantry (front and rear arms) |

|

Mounting Speed |

82000cph (optimal) |

|

Mounting Accuracy |

(XY)±0.035mm CPK≥1.0 |

|

Component Height |

≤12mm |

|

Component Type |

01005/0201/0402/0603~5050/SOT/SOP/QFP/QFN/BGA, etc. (resistor/capacitor/diode/triode/LED/IC, etc.) |

|

Component Range |

Inch size 01005 to 36mm*36mm, and larger components mounting. |

|

PCB Thickness |

0.6mm~3.5mm |

|

PCB Size |

Single lane 520mm(L)×50-450mm(W) ; Dual lane 520mm(L)×50-250mm(W) |

|

PCB Conveying |

Built-in automatic transmission system |

|

Nozzle Change |

Automatic nozzle change (31-hole nozzle library*2 gantry) |

|

Control System |

Built-in industrial computer (Windows 7) with dual monitors, keyboard and mouse |

|

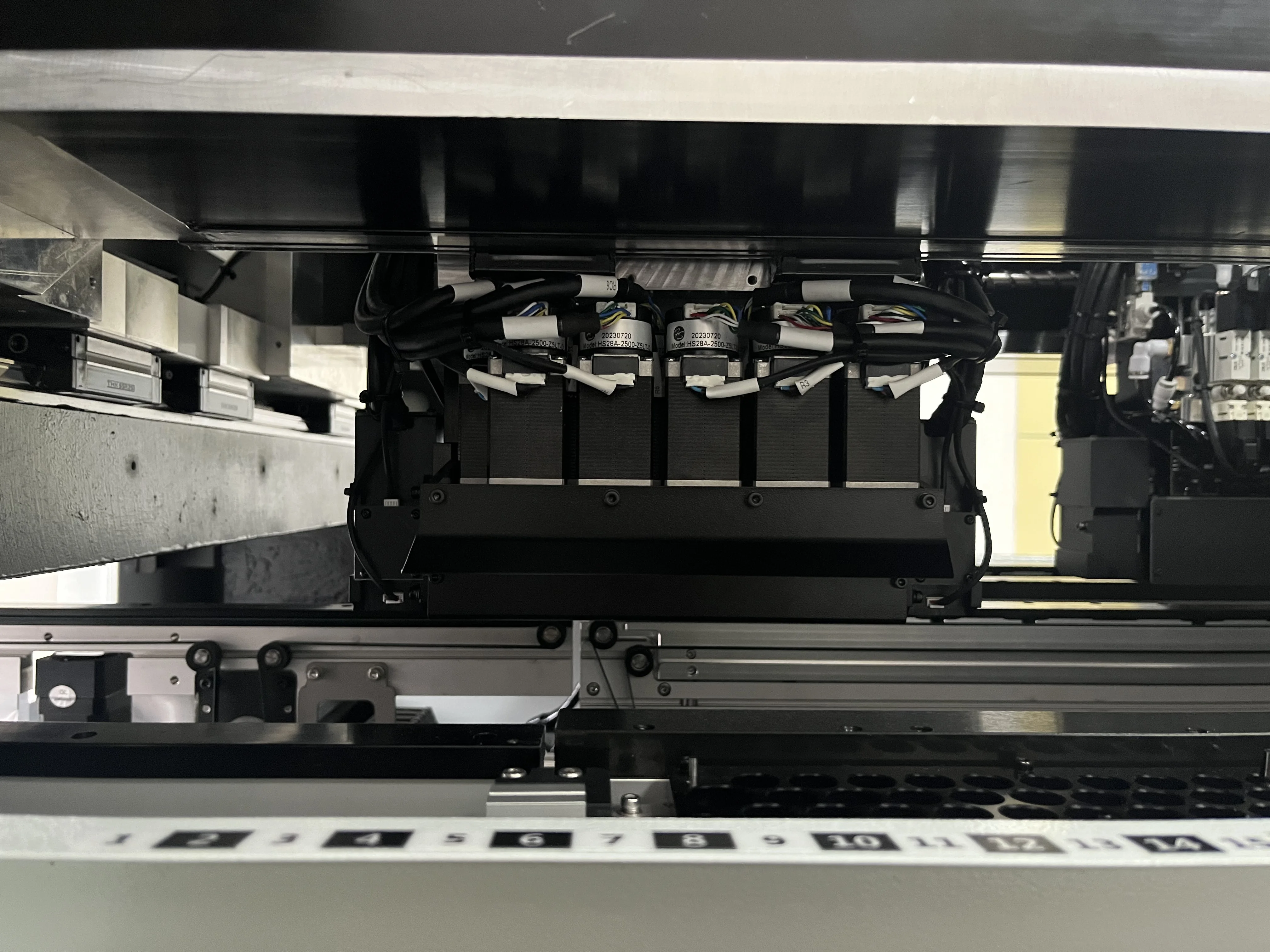

Drive System |

Y-axis double linear motor X-axis Panasonic servo motor |

|

Transmission System |

Y-axis THK linear guide, X-axis THK linear guide and lead screv |

|

Feeding System |

100 NXT 8mm standard feeder stacks (also suitable for IC tray and stick feeder) |

|

Vision System |

Fly camera:10*2 (component size applicable: 15mm×15mm); Mark camera:2*2 sets |