Understanding SMT Pick and Place Machine Fundamentals

What Is an SMT Pick and Place Machine?

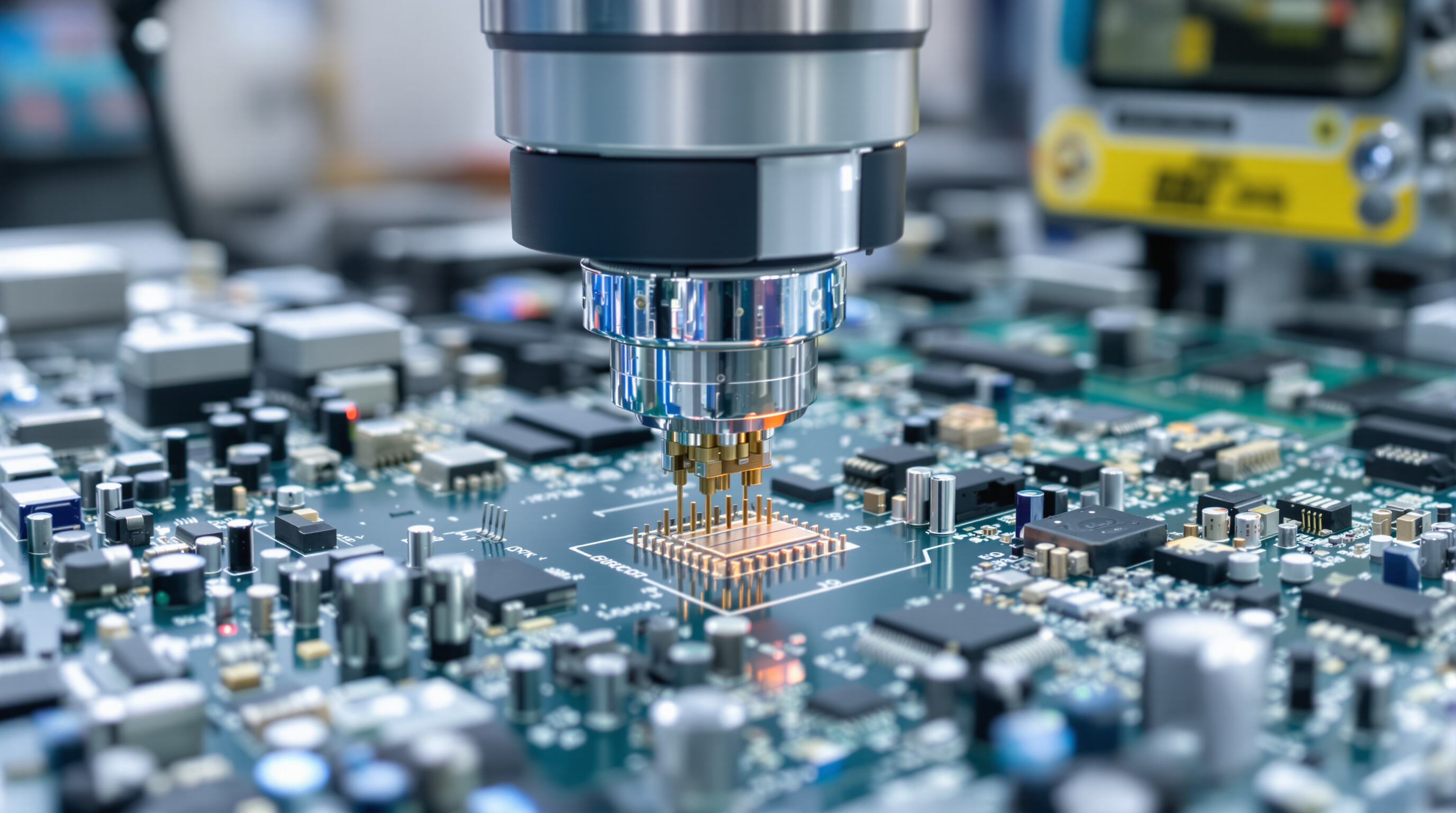

The SMT (Surface Mount Technology) pick and place machine is basically what makes it possible to put tiny electronic components on those printed circuit boards we see everywhere nowadays. These machines work with robotic arms and smart feeder systems to place really small parts like resistors and integrated circuits onto boards covered in solder paste. Some of the faster models can do over 50 thousand placements every single hour, which is absolutely mind blowing when you think about how small those components actually are. When manufacturers switch from hand assembly to these automated systems, they pretty much get rid of all those positioning mistakes that happen when people try to place such tiny parts manually. Plus, production just goes so much faster, which means factories can churn out way more products without sacrificing quality.

The Role of Surface Mount Technology in Modern PCB Assembly

Surface mount tech changed how we make electronics because it lets parts sit right on top of printed circuit boards instead of needing wires pushed through holes. The difference is huge actually - components can be about 80% smaller and circuits packed 70% denser than old school through-hole techniques according to that Electronics Journal report from last year. Why does SMT rule today's factories? Well, think about all those tiny gadgets we carry around now. Smartphones would still fit in our pockets if not for this tech, same goes for things like pacemakers or insulin pumps that need compact yet powerful electronics inside them.

Core Functionality and Importance in PCB Assembly

These machines perform three essential functions:

- Component Retrieval: Vacuum nozzles extract parts from reels or trays

- Precision Alignment: Vision systems verify orientation with 10-micron accuracy

- Placement & Verification: Components are deposited at programmed coordinates, with pressure sensors confirming contact

| Impact Parameter | Manual Assembly | SMT Pick and Place Machine |

|---|---|---|

| Placements Per Minute | 6 | 1,500 |

| Defect Rate * | 1.8% | 0.01% |

| *Industry benchmark data (IPC Validation Study 2024) |

This integration reduces component waste by 38% and slashes assembly costs by 45%, making SMT machines essential for achieving Six Sigma quality standards in mass production while maintaining market competitiveness.

Types of SMT Pick and Place Machines and Their Applications

Manual and Desktop Systems for Prototyping and Low-Volume Production

For small batch electronics work, manual SMT pick and place machines provide good value without breaking the bank. These smaller units come with hand operated vacuum tips and visual guides that help techs line up parts properly on circuit boards. They're especially popular in research settings and when testing new product ideas. Most benchtop versions can manage boards around 300 by 200 millimeters in size, placing components at rates between five hundred to three thousand per hour depending on setup. What makes them so appealing is how straightforward they are to operate. No complicated programming needed, just grab and place as needed during prototype testing phases. Many university labs and startup workshops have adopted this approach because it cuts down on what would otherwise be expensive outsourced assembly work. The savings can reach about sixty percent while still keeping component placement within twenty five microns of perfection.

Fully Automatic SMT Pick and Place Machines for High-Volume Lines

The heart of modern high speed production lines lies in fully automatic SMT pick and place machines. These advanced systems come with multiple nozzle heads and tape reel feeders that let them reach speeds over 30 thousand components per hour while keeping placement accuracy around plus or minus five microns. What makes them really stand out is their built in vision technology which scans those reference marks and checks component positions as they go along, making tiny adjustments to the path almost instantly. Factories across automotive and consumer electronics sectors have adopted these machines for round the clock operations. They cut down on labor expenses by roughly 85 percent and keep defects at an incredibly low level, usually under 0.01 percent according to industry reports.

Comparative Analysis: Throughput, Accuracy, and Cost of Ownership

Selecting the right SMT machine requires balancing performance against investment. The key differences are:

| Feature | Manual/Desktop Systems | Fully Automatic Machines |

|---|---|---|

| Throughput | 500–3,000 CPH | 30,000–100,000+ CPH |

| Placement Accuracy | ±25 microns | ±5–10 microns |

| Initial Investment | $5K–$20K | $50K–$500K+ |

| Operating Cost/Hour | $8 (labor-intensive) | $1.5 (automation-powered) |

A 2025 global survey of PCB assembly infrastructure found that high-volume facilities recover automation investments within 18–24 months, driven by 93% higher daily output. In contrast, low-mix operations benefit from the flexibility and minimal maintenance of manual systems.

Key Technological Features of Advanced SMT Pick and Place Systems

Micron-Level Precision in Component Placement

Modern SMT pick and place machines achieve placement accuracy within ±25µm (2025 Surface Mount Technology Report), enabling reliable assembly of 0201 chips, micro-BGAs, and ultra-fine-pitch components. This precision reduces rework rates by 62% compared to earlier systems and supports the demands of next-generation IoT and wearable devices.

High-Speed Operation for Maximum Production Efficiency

Top-tier systems process up to 77,000 components per hour (CPH) without sacrificing accuracy, thanks to synchronized multi-head architectures. A 2025 industry analysis showed these machines reduced cycle times by 28% in automotive ECU production, directly enhancing production scalability.

Integrated Vision Systems for Real-Time Alignment

Advanced vision systems provide:

- Sub-pixel optical recognition for automatic orientation correction

- 3D solder paste inspection to prevent tombstoning

- Adaptive lighting that reduces misalignment errors by 91% (2025 Flexible Electronics Assembly Study)

These capabilities ensure consistent accuracy across diverse component types and board layouts.

Modular Design and Scalability for Future-Proofing Production

Leading SMT machines feature modular designs that support:

- Feeder swaps in under five minutes for fast product changeovers

- Expandable nozzle sets handling components from 01005 to 150mm²

- Cloud-connected firmware updates for compliance with evolving IPC standards

This flexibility allows manufacturers to scale capacity and adapt to new technologies without replacing entire systems.

AI and Smart Automation: The Future of SMT Pick and Place Technology

Machine learning algorithms now predict maintenance needs with 89% accuracy, reducing unplanned downtime by 47%. Generative AI optimizes placement sequences, with projections indicating a 33% increase in line efficiency by 2026 (2025 Global SMT Automation Trends Report). These advancements mark a shift toward self-optimizing, intelligent assembly lines.

Operational Benefits of Automating PCB Assembly with SMT Pick and Place Machines

Boosting Speed and Efficiency in High-Volume Manufacturing

The latest SMT pick and place machines are blowing away traditional manual assembly methods, cutting cycle times by as much as half according to the SMT Industry Report from last year. This speed boost helps manufacturers keep up with all those smartphones, smartwatches, and other connected gadgets people want these days. When companies automate the whole process from component feeding to precise placement on circuit boards, they basically eliminate wasted time between operations. The machines just keep going nonstop without breaks. A recent industry study in 2024 showed some impressive numbers too. Factories that switched to automated SMT systems saw their hourly production jump by about 12.4%, while also saving nearly 18% on energy costs. These kinds of improvements make a huge difference in industries where volume matters most, especially when it comes to making parts for cars and other complex electronic systems.

| Manual vs. Automated Assembly | Manual | Automated SMT |

|---|---|---|

| Components Placed/Hour | 800 | 85,000+ |

| Defects per Million (DPM) | 900 | <15 |

| Labor Cost Contribution | 62% | 9% |

Minimizing Human Error and Enhancing Process Consistency

SMT machines that are automated take out all the guesswork from manual assembly thanks to their closed loop calibration systems and those high res vision inspections that can spot issues down to 15 microns. When components get misaligned during production, these machines fix them right away without stopping the line. According to research from Ponemon Institute back in 2023, factories of moderate size saved around $740,000 each year just on reduced rework costs alone. And things keep getting better as machine learning gets smarter over time. Top manufacturers have noticed something pretty impressive happening after about half a year with AI optimization running in the background. They're seeing anywhere between 30% and 50% drop in soldering problems across their operations.

Improving Yield Rates and Product Quality in Automated Assembly

When manufacturers standardize how they handle and place components, their SMT pick and place systems can hit first pass yields over 99.2% on modern production lines. This makes products much more reliable overall. For example, automotive tier one suppliers saw around a 22% drop in warranty issues once they switched from manual to automated assembly for those ADAS control boards. The machines have real time thermal monitoring and special heads that apply just the right amount of pressure when placing tiny parts. This protects delicate components such as those 0.01 inch by 0.005 inch capacitors that would easily get damaged otherwise. Plus it keeps everything compliant with those important quality standards like ISO 9001 and the strict IPC A 610 class 3 requirements for high reliability electronics.

Leading Manufacturers and Market Trends in SMT Pick and Place Equipment

Top Brands: Juki, Panasonic, Yamaha, ASM, Mycronic, and Hanwha

Innovation keeps pushing forward in the SMT pick and place market, thanks largely to big names like Juki, Panasonic, Yamaha, ASM, Mycronic, and Hanwha. What sets these players apart? They battle it out over how fast they can work, how precise their placements are, and how well their machines integrate into production lines. Reliability matters too, along with quick setup times and good networking features for those smart factories everyone talks about now. The range of products available means plant managers aren't stuck with one-size-fits-all solutions. Instead, they get to pick equipment that matches exactly what their operation needs in terms of output levels and component complexity requirements.

Innovations Driving Growth in the SMT Placement Market

Recent advancements include vision systems capable of detecting sub-25µm deviations, AI-powered predictive maintenance, and modular platforms with IoT connectivity for real-time monitoring. These technologies enable throughput of up to 85,000 components per hour while maintaining placement accuracy below 15µm, pushing the boundaries of production efficiency.

Global Demand for Automated and Intelligent PCB Production Systems

The Asia Pacific region dominates when it comes to adopting surface mount technology equipment, taking about 62% of the total market share thanks largely to those massive manufacturing centers in China and Taiwan. Things are looking up in North America too, where companies across aerospace and defense sectors are increasingly investing in smart factory solutions. Recent studies of manufacturing trends show clearly that more and more plants are jumping on the automation bandwagon as they upgrade their entire supply chain operations. Smart placement machines which cut down on setup time continue to be popular all around the globe, with many manufacturers finding these systems essential for staying competitive in today's fast paced production environment.

Frequently Asked Questions (FAQ)

What is the main advantage of using SMT pick and place machines?

The primary advantage is the improvement in precision and speed, leading to higher production efficiency and reduced defect rates. These automated systems significantly outperform manual assembly, making them essential in modern manufacturing.

How do manual and automatic SMT machines differ in terms of application?

Manual SMT machines are ideal for prototyping and low-volume production, offering flexibility and lower costs. Automatic SMT machines are designed for high-volume production, providing rapid processing speeds and greater accuracy.

What technological advancements have influenced modern SMT machinery?

Advancements include micron-level precision, high-speed operation, integrated vision systems, modular designs, AI and smart automation, enhancing production efficiency and adaptability.

Which regions dominate the market for SMT pick and place machines?

Asia Pacific leads the market due to its extensive manufacturing centers, especially in China and Taiwan, followed by North America, which sees increasing investments in smart factory solutions.

Table of Contents

- Understanding SMT Pick and Place Machine Fundamentals

- Types of SMT Pick and Place Machines and Their Applications

- Key Technological Features of Advanced SMT Pick and Place Systems

- Operational Benefits of Automating PCB Assembly with SMT Pick and Place Machines

- Leading Manufacturers and Market Trends in SMT Pick and Place Equipment

- Frequently Asked Questions (FAQ)