Understanding Pick and Place Machines: Core Differences

Defining Manual vs. Automated Pick and Place Systems

The difference between manual and automated pick and place systems in PCB assembly is significant. Manual pick and place systems require human operators to place each component precisely, demanding a high level of skill and painstaking attention to detail. While this method offers greater flexibility for unique or low-quantity tasks, it can be slow and is prone to human error and fatigue, which often leads to inconsistencies in the final product. On the other hand, automated systems use robotics and sophisticated software to execute these tasks. This approach reduces potential errors and increases assembly speeds significantly, with studies suggesting improvements of up to 60% in PCB assembly efficiency. Automated systems shine in high-volume productions where speed and accuracy are paramount, whereas manual systems may still be preferred in bespoke manufacturing or prototyping due to their flexibility.

Key Components of PCB Assembly Automation

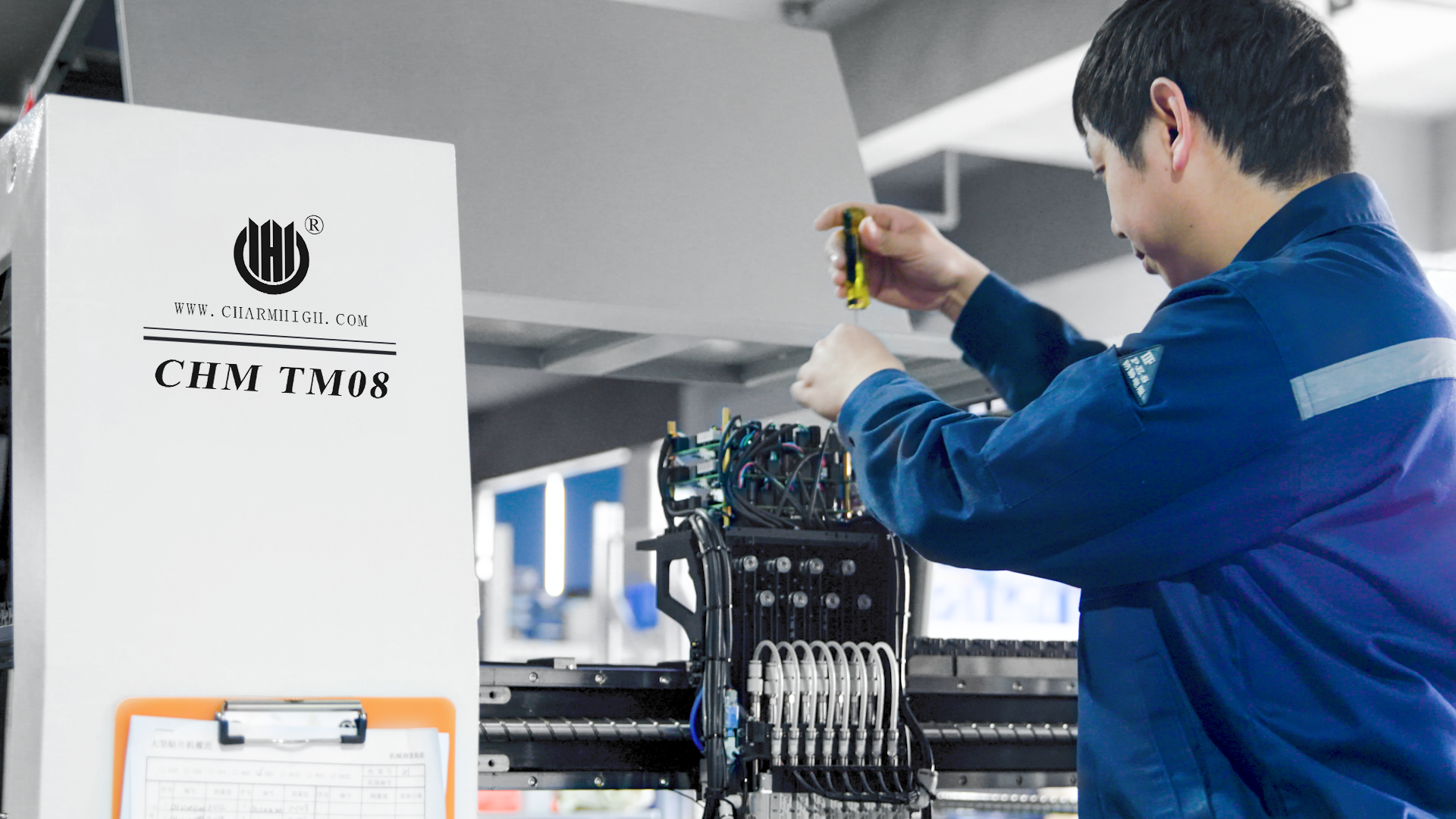

Automated pick and place systems consist of several critical components that work together to enhance the efficiency of PCB assembly. The main elements include feeders that supply components to placement heads, which then precisely position parts on the PCBs. These components are transferred via transport conveyors, ensuring a continuous and smooth flow of materials. Software integration plays a crucial role in orchestrating these components, optimizing operations by managing placement paths and providing real-time feedback. Innovations like component tracking and real-time data analysis further boost the accuracy and reliability of these systems, making them indispensable in modern manufacturing. By ensuring all parts of the system operate seamlessly together, automated systems achieve high levels of precision and quality, critical to PCB assembly automation's success.

Manual vs. Automated: Operational Workflows Compared

Human-Driven Assembly: Workflow Challenges

In human-driven assembly workflows, maintaining consistency and efficiency presents several challenges. Human factors such as fatigue and skill variability contribute significantly to error rates, with studies indicating that human errors can account for approximately 30% of assembly defects. To mitigate these challenges, it’s essential to implement strategies like improved training programs and ergonomic workstation design. Such measures can help reduce the physical strain on operators and enhance their focus and productivity. Despite its challenges, one advantage of manual systems is its flexibility; they can easily adapt to changes in design or small-batch production, unlike the more rigid nature of automated workflows.

Automated Pick and Place System Efficiency

Automated pick and place systems are a cornerstone of enhancing time efficiency in electronic assembly. Unlike human-driven processes, automated systems can process components at significantly faster speeds, translating to increased throughput and shorter cycle times. Metrics from industry examples reveal stark improvements in productivity, with such systems often achieving higher assembly volumes and speeds than their manual counterparts. Numerous case studies demonstrate that companies transitioning to automated systems have experienced marked upticks in efficiency, aligning with the reality that automation minimizes human-related errors and operational bottlenecks.

Role of Vision Systems in SMT Production Lines

Vision systems play a crucial role in optimizing SMT production lines, enhancing the precision of automated pick and place operations. These sophisticated systems, incorporating advanced cameras and AI algorithms, ensure components are placed accurately and can swiftly detect any misalignments. The technology significantly contributes to error reduction, aligning with industry standards for machine vision, which are crucial for achieving seamless production flows. By elevating the accuracy of component placement, vision systems help boost overall efficiency, ensuring high-quality outcomes in high-demand electronic manufacturing environments.

By examining these operational workflows, we can appreciate the nuanced benefits and challenges each system presents. Whether opting for the flexibility of manual systems to achieve bespoke manufacturing needs or leveraging the efficiency of automated processes remains crucial to aligning production capacities with evolving industry demands.

Precision and Speed in PCB Assembly

Accuracy Metrics: Manual vs. Robotic Placement

In PCB assembly, accuracy is a critical factor impacting overall product performance. Manual assembly techniques often have varying accuracy levels due to human error, skill variability, and fatigue. Specific industry reports highlight that robotic systems can achieve placement accuracy rates exceeding 99%, whereas manual processes frequently fall short of these marks. This disparity arises because even minor errors can compound, resulting in significant performance issues in the final electronic products. Thus, robotic placement systems not only ensure higher precision, but they also significantly minimize defects in assembly, making them indispensable for high-quality production lines.

Handling Miniaturized Components (e.g., 0201 Resistors)

As electronic devices continue to shrink, the challenges of handling miniaturized components become more pronounced, especially in manual assembly. Tiny components like 0201 resistors pose difficulties in precise placement due to their size. Automated systems, however, utilize advanced tools and techniques, such as pick-and-place machines integrated with vision systems, to enhance placement accuracy. Industries like consumer electronics and telecommunications, which demand product miniaturization, heavily rely on these automated systems to achieve the necessary precision in component placement, avoiding the pitfalls of manual errors.

Impact of Rotation Control on Yield Rates

Rotation control in automated PCB assembly systems plays a pivotal role in ensuring precise component orientation, directly affecting yield rates. In a study within the industry, data indicated that improved rotation control could significantly reduce defects, enhancing yield rates and product performance. Ensuring correct component orientation is crucial as it impacts the functionality and reliability of electronic devices. Thus, automated systems equipped with advanced rotation control techniques contribute to maintaining high efficiency and quality in assembly lines, addressing one of the key areas where manual processes often falter.

Choosing Based on Production Scalability

Low-Volume Prototyping: When Manual Makes Sense

Manual pick and place machines are often ideal for low-volume prototyping due to their cost-effectiveness and flexibility. These machines allow for easy design modifications without the need for complex reprogramming, which is beneficial in the initial stages of product development. Small businesses, in particular, find manual systems advantageous as they can adapt quickly to changes in design and offer significant savings on labor costs. An example of a company that successfully utilized manual pick and place methods during prototyping is a startup in the wearable technology sector, which reported reduced initial investment and seamless design iterations.

High-Speed Manufacturing Demands

The demand for high-speed manufacturing continues to grow as industries strive for increased efficiency and productivity. Automated pick and place systems address these demands by significantly enhancing production rates and minimizing errors. For instance, some automated systems can achieve up to a 200% increase in output efficiency compared to manual methods. These systems are designed to handle fluctuations in production demands, ensuring consistent quality without sacrificing speed. The adaptability of automated machines makes them particularly suited for large-scale operations where rapid processing and high precision are critical.

Integration with Full SMT Production Line Automation

Integrating automated systems into SMT production lines results in enhanced productivity and more streamlined operations. Technologies such as pick and place machines, reflow ovens, and inspection systems work together to create a cohesive automated production environment. This integration ensures that every aspect of assembly is optimized, leading to higher quality outputs and reduced cycle times. Successful case studies highlight companies that have implemented full automation in their production lines, reporting substantial improvements in operational efficiencies. This collaborative approach not only boosts productivity but also ensures that the production process is robust and adaptable to future technological advancements.