Разбиране на Машини за Взимане и Поставяне: Основни Разлики

Дефиниране на Ръчни Срещу Автоматизирани Системи за Взимане и Поставяне

При сравнение на ръчни и автоматизирани системи за монтаж на компоненти върху PCB платки, липсата на съвпадение между тях е значителна. При ръчните системи работниците трябва да поставят всяка една компонента в ръчна работа. Това изисква истински умения и голяма концентрация, за да се постигне прецизност. Разбира се, този метод работи добре при единични поръчки или малки серии, но нека си признаем – просто е бавно. Хората правят грешки, когато са уморени, а компонентите се оказват на грешни места или несъответстващи на подравняването. Автоматизираните системи разказват съвсем различна история. Те разчитат на роботи, управлявани от интелигентен софтуер, които извършват цялата тежка работа. Резултатът? По-малко грешки и далеч по-бързи производствени темпове. Някои проучвания показват, че тези машини могат да увеличат ефективността на монтажа на PCB с около 60%. Това прави автоматизацията идеална за масово производство, където най-важното е скоростта. Въпреки това ръчните методи все още се използват, особено когато компаниите имат нужда от персонализирани конструкции или прототипи, тъй като предлагат допълнителна гъвкавост, която понякога липсва при машините.

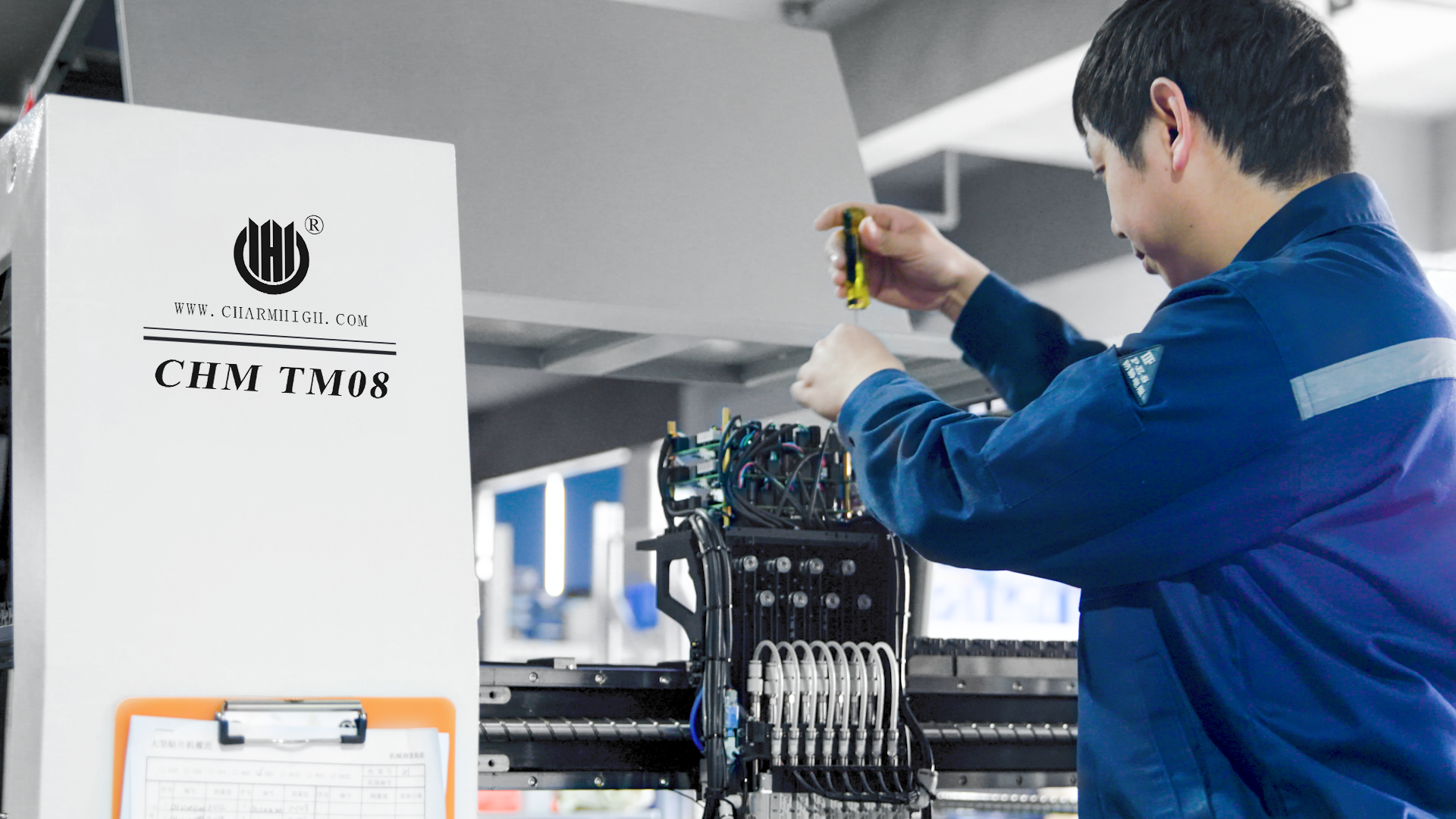

Ключови компоненти на автоматизацията при монтажа на ПЛС

Системите за вземане и поставяне за автоматизирана монтажна събираемост на PCB разчитат на множество ключови компоненти, работещи в синхрон, за да ускорят процеса. В самия му център са подавателите, които предават компонентите към онези модерни глави за поставяне, които поставят всичко точно на мястото му върху платките. Целият процес се движи благодарение на транспортни ленти, които осигуряват непрекъснато движение на материала. Софтуерът всъщност е това, което свързва всичко заедно, като определя къде всеки компонент трябва да отиде и правейки корекции по време на процеса, когато нещо не изглежда правилно. Нови технологични добавки, като проследяването на отделни компоненти и анализирането на данни в реално време, наистина повишиха точността на тези машини до напълно ново ниво. Те просто работят толкова добре заедно, че производителите могат да разчитат на постоянно висококачествени резултати. Точно тази надеждност прави тези системи задължителен елемент за всеки, който е сериозен относно ефективното производство на PCB в днешно време.

Ръчно срещу Автоматично: Сравнение на операционни работни процеси

Човешки-Дривен Монтаж: Проблеми при работния процес

Линиите за сглобяване, обслужвани от хора, срещат сериозни проблеми при поддържането на последователност и гладко функциониране ден след ден. Хората се уморяват, уменията се различават между отделните работници, а всички тези човешки фактори водят до грешки. Проучвания показват, че около една трета от всички дефекти при сглобяването се дължат просто на човешка грешка. Добрата новина е, че има начини да се справим с това. По-добра подготовка на персонала и работни места, проектирани с комфорт в предвид, допринасят значително за намаляване на грешките. Тези промени не само улесняват работниците, но и ги поддържат фокусирани и продуктивни през цялата смяна. Въпреки това, ръчното сглобяване има едно предимство – гъвкавостта си. Когато се променят дизайни или компаниите трябва да произведат по-малки серии, човешките ресурси обикновено могат да се справят с прехода без особен проблем. Автоматизираните системи не са толкова гъвки в тези ситуации, често изисквайки сериозно преprogramиране, за да се направят и най-малки корекции.

Ефективност на автоматизирана система за взимане и поставяне

Автоматизацията при позициониране и монтиране е станала незаменима за спестяване на време по време на електронна монтажна работа. Тези машини просто надминават възможностите на хората, когато става въпрос за поставяне на компоненти върху платки. Те обработват компоненти далеч по-бързо, отколкото всеки работник би могъл, което означава, че фабриките произвеждат повече продукти на ден и съкращават времето за изготвяне на всеки артикул. Анализът на реални данни от производствените площи показва значително увеличение на показателите за продуктивност. Монтажните линии, използващи тези автоматизирани системи, постоянно достигат производствени цели, които биха били невъзможни само с ръчна работа. Много производители, преминали към автоматизация, отбелязват очевиден ръст в скоростта на производство. Всъщност това е логично, защото роботите не правят онези малки грешки, които понякога хората допускат, нито създават закъснения, докато чакат работниците да се справят с предходни задачи.

Ролята на визуалните системи в SMT производствени линии

Системите за визия са от съществено значение за постигане на максимален капацитет на производствените линии SMT, особено когато става въпрос за гарантиране правилното функциониране на автоматизираните машини за вземане и поставяне. Тези системи по същество съчетават интелектуални камери с някои доста интересни AI софтуерни приложения, които проверяват дали компонентите се поставят там, където трябва и бързо идентифицират проблеми, преди те да се превърнат в по-големи въпроси. Основната ценност на тази технология се състои в това колко значително се намалят грешките по време на производството. Повечето фабрики следват определени стандарти за качество на машинното виждане, а тези системи просто съответстват на тези изисквания, като в същото време поддържат процесите на фабричната площадка да текат гладко. Когато компонентите се поставят правилно всеки път, целият производствен процес се ускорява, без да се жертва качеството, което е от голямо значение на днешния конкурентен пазар на електроника, където търсенето никога не изглежда да намалява.

Чрез разглеждането на тези операционни работни процеси, можем да оценим деликатните предимства и предизвикателства, които всяка система представя. Дали да се избере гъвкавостта на ръчните системи за постигане на специфични производствени нужди или да се използва ефективността на автоматизирани процеси, остава важно за съгласуване на производствените капацитети с променящите се индустриални изисквания.

Точност и бързина при монтажа на ПЛС

Метрики за точност: Ръчно срещу роботизирано поставяне

Когато става въпрос за монтаж на печатни платки, много е важно нещата да се правят правилно, за да работи добре крайният продукт. Хората, които извършват монтажа ръчно, понякога правят грешки. Точността им доста варира, в зависимост от умората им, уменията, които притежават, и просто човешки грешки. Има и интересни данни от индустрията по въпроса. Роботите могат да поставят компоненти с над 99% точност през повечето време, докато при ръчните методи трудно се постига такава стабилност. Разликата е съществена, защото малки грешки по време на монтажа могат да доведат до големи проблеми по-късно, когато електрониката трябва да работи правилно. Затова много производители сега разчитат сериозно на роботизирани системи за поставяне на компоненти. Тези машини намаляват грешките и дефектите, което е логично, ако компаниите искат да поддържат стандартите за качество през цялата серийна продукция.

Обработка на миниатюризираните компоненти (например, резистори 0201)

Продължаващата тенденция към по-малка електроника създава сериозни предизвикателства, когато се налага работа с миниатюрни компоненти, особено за всеки, който се опитва да ги сглоби ръчно. Вземете например онези малки резистори 0201 – те са толкова малки, че дори най-малкото отместване по време на сглобяването може да съсипе цяла платка. Тук идва моментът, в който автоматизацията се намесва със своите изискани машини. Машини за пикап и поставяне, оборудвани с камери с високо разделително способност, правят неща, които човешките пръсти просто не могат да осъществят в този мащаб. За индустрии, които изпробват границите на миниатюризацията – като производителите на смартфони или създателите на компактни телекомуникационни устройства, тези автоматизирани решения са практически незаменими. Без тях риска от скъпи грешки при ръчното сглобяване ще бъде твърде висок, за да бъде поносим в днешния конкурентен пазар.

Влияние на контрола на врътенето върху процентите на производствена отдача

Правилният контрол на въртенето в автоматизираните системи за монтаж на PCB играе ключова роля за правилното позициониране на компонентите, което в крайна сметка влияе върху броя качествени платки, произведени на линията. Наскорошни изследвания показаха, че подобреният контрол на въртенето значително намалява дефектите, което води до по-висок добив и по-добро общо представяне на продуктите. Когато компонентите не са правилно ориентирани по време на монтажа, цели вериги могат да се провалят или да работят непредсказуемо по-късно. Затова модерните автоматизирани системи използват тези напреднали системи за контрол на въртенето. Те помагат производството да протича гладко, без грешките, които са чести при по-старите ръчни методи за монтаж, особено когато се работи с миниатюрни повърхностно монтирани компоненти, изискващи точно позициониране.

Избор по скалабилност на производството

Прототипиране с нисък обем: Кога ръчният начин е уместен

За малки поръчки при прототипирането, ръчни машини за позициониране обикновено работят много добре, защото не са скъпи и могат да се справят с най-различни задачи. Това, което ги прави толкова добри за ранната фаза на разработване на продукти, е фактът, че много лесно може да се променят дизайни, без да се налага да се пренаписва отново сложно програмиране. Много собственици на малки предприятия харесват тези системи, тъй като те бързо реагират на промени в спецификациите на дизайна и спестяват разходи за наемане на допълнителна работна ръка за сглобирането. Вземете например една стартираща компания в сферата на носимите технологии. Те разчитаха изключително много на ръчни методи за позициониране по време на фазата на прототипиране и отбелязаха значително намаляване на първоначалните разходи, като в същото време можеха да тестват множество версии на дизайна без сериозни закъснения.

Изисквания при високоскоростно производство

Производители в различни сектори постоянно се стремят към по-бързи темпове на производство, тъй като конкуренцията в глобалните пазари се засилва. Автоматизацията при позициониране директно отговаря на тази нужда, като увеличава обема на производството и намалява скъпоструващите грешки по време на сглобяването. Някои напреднали системи всъщност удвояват обема, който работниците биха могли да постигнат ръчно за същия период от време. Онова, което отличава тези машини, е тяхната способност да се адаптират към променящите се обеми на производство от ден на ден. Завод, работещ на пълна мощност една седмица, може следващата седмица да намали интензивността на производството си в резултат на промени на пазара, но автоматизираните линии осигуряват постоянство в качеството на продукцията, независимо от колебанията в натовареността. Тази гъвкавост обяснява защо големите автомобилни заводи и производители на електроника разчитат в голяма степен на подобни системи, където всяка секунда има значение, а микроскопични отклонения определят дали продуктите отговарят на изискванията или попадат в боклука.

Интеграция с пълен SMT производствен линейен автоматизъм

Когато производителите внедрят автоматизация в линиите си за производство на повърхностно монтирани компоненти (SMT), те обикновено постигат по-добра продуктивност и по-плавна ежедневна работа. Комбинацията от различни технологии като машини за поставяне на компоненти, големите рефлусни фурни, които всички познаваме, както и различни системи за инспекция, създава нещо доста близко до напълно автоматизирана фабрична зала. Повечето хора ще ви кажат, че когато всичко работи съвместимо и правилно, целият процес на сглобяване се оптимизира напълно. Качеството се подобрява, докато циклите на производство значително се съкращават. Вземете например XYZ Electronics – те заложиха изцяло на автоматизация миналата година и отчетоха скок в производството с почти 30% само за шест месеца. Разбира се, винаги има някакви пречки по пътя, но в крайна сметка тези интегрирани системи помагат производството да остане стабилно, дори и с появата на нови технологии на всеки няколко години.