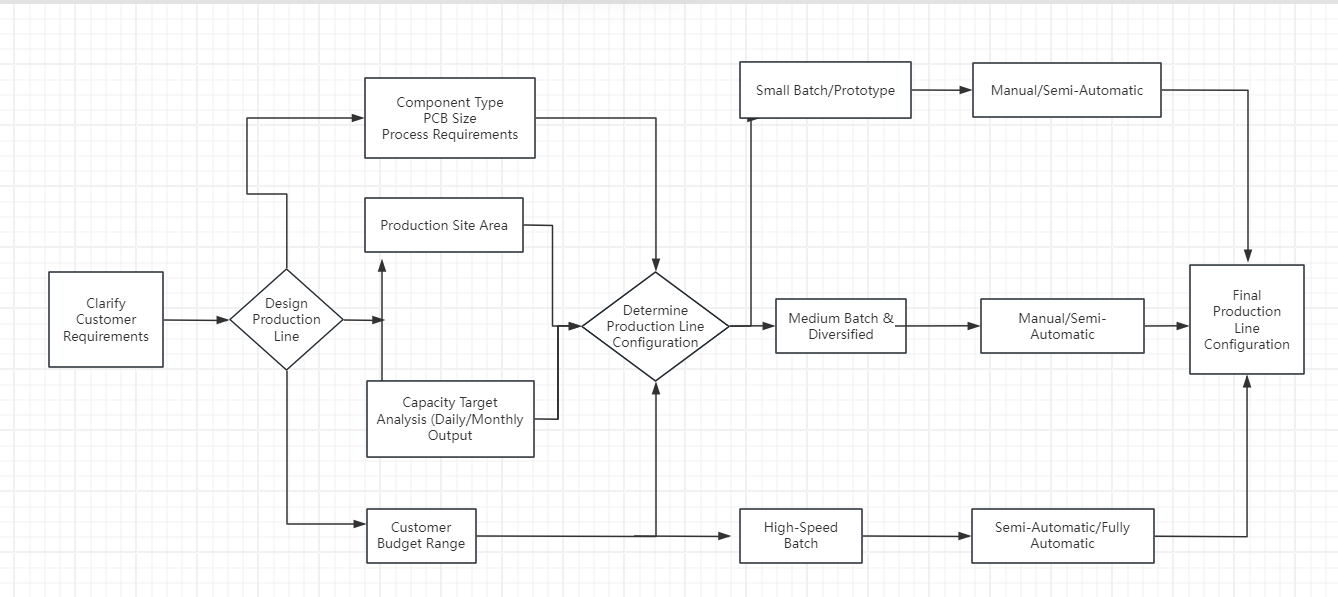

1. Understanding component types: Select appropriate printer, pick and place machine, and corresponding inspection equipment based on component size (whether there are high-precision components such as 01005, 0201, BGA, and chips);

2. Understanding PCB dimensions: This is one of the key factors in evaluating the board loader machine, unloader machine, printer, pick and place machine, conveyor, reflow oven, and corresponding inspection equipment;

3. Production site: This is the main basis for SMT production line design.

4. Understanding transportation routes: This involves the necessary access routes for equipment to be transported into the production site, requiring detailed understanding and communication with the customer in advance;

5. Capacity analysis: Typically, when a pick and place machine is used as a general-purpose machine, the capacity is in the range of 40%-70% of the optimal speed. If more accurate capacity is required, the customer needs to provide corresponding documents for simulation testing;

6. Customer's budget range: This determines the level of the production line, and the ability to plan according to the customer's budget is necessary. 1. Prototyping/R&D Solutions: Semi-automatic and Fully Automatic Types (Specify length + machine name and optimal capacity)

1. Prototyping/R&D Solutions: Semi-automatic and Fully Automatic Types

Semi-automatic prototyping production line:

The total length is approximately 5.72m, and the optimal production line speed is 14400 CPH

Fully automatic production line

The total length is approximately 9.63m, and the optimal production line speed is 27800 CPH

2. Medium-volume/Flexible Fully Automatic SMT Production Line

The total length is approximately 12.76m, and the optimal production line speed is 80000 CPH.

Loader machine + Printer + Conveyor + Pick and place machine RS10 + Conveyor + TM08 + Conveyor + Rail reflow oven + Unloader machine

The total length is approximately 12.25m, and the optimal production line speed is 62800 CPH.

Loader machine + Printer + Conveyor + Pick and place machine TM08 + Conveyor + TC06 + Conveyor + Rail reflow oven + Unloader machine

The total length is approximately 11.82m, and the optimal production line speed is 55600 CPH.

Loader machine + Printer + Conveyor + Pick and place machine TC06 + Conveyor + TC06 + Conveyor + Rail reflow oven + Unloader machine

3. High-speed Fully Automatic SMT Production Line

The total length is approximately 14.34m, and the optimal production line speed is 127000 CPH.

Loader machine + Printer + Conveyor + Pick and place machine RS20 + Conveyor + RS10 + Conveyor + Rail reflow oven + Unloader machine

The total length is approximately 15.32m, and the optimal production line speed is 165000 CPH.

Loader machine + Printer + Conveyor + Pick and place machine RS12 + Conveyor + Pick and place machine RS12 + Conveyor + RS10 + Conveyor + Rail reflow oven + Unloader machine

Other inspection equipment can be added as needed.

Hot News

Hot News