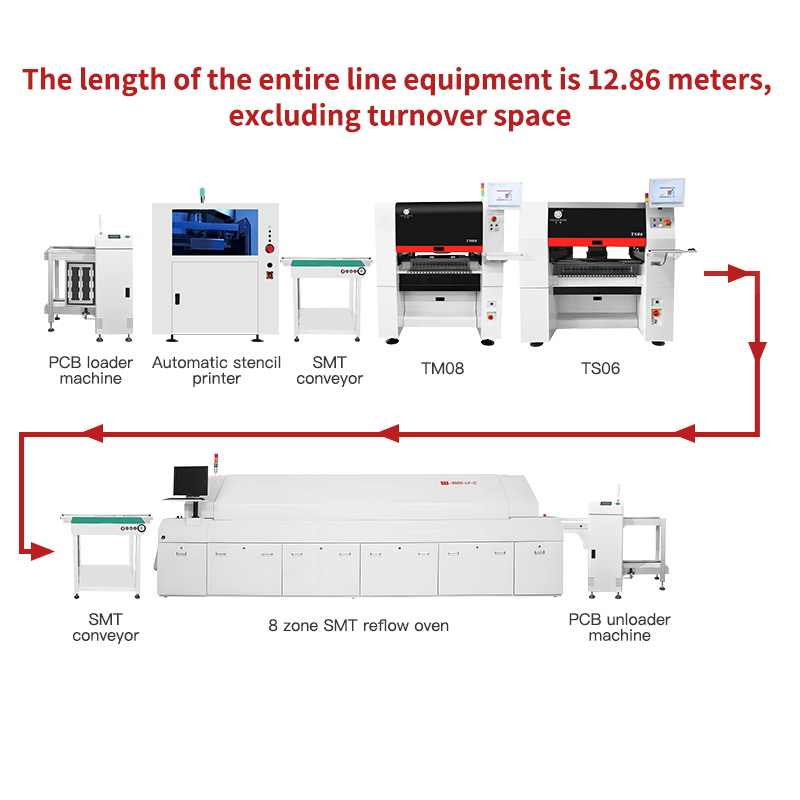

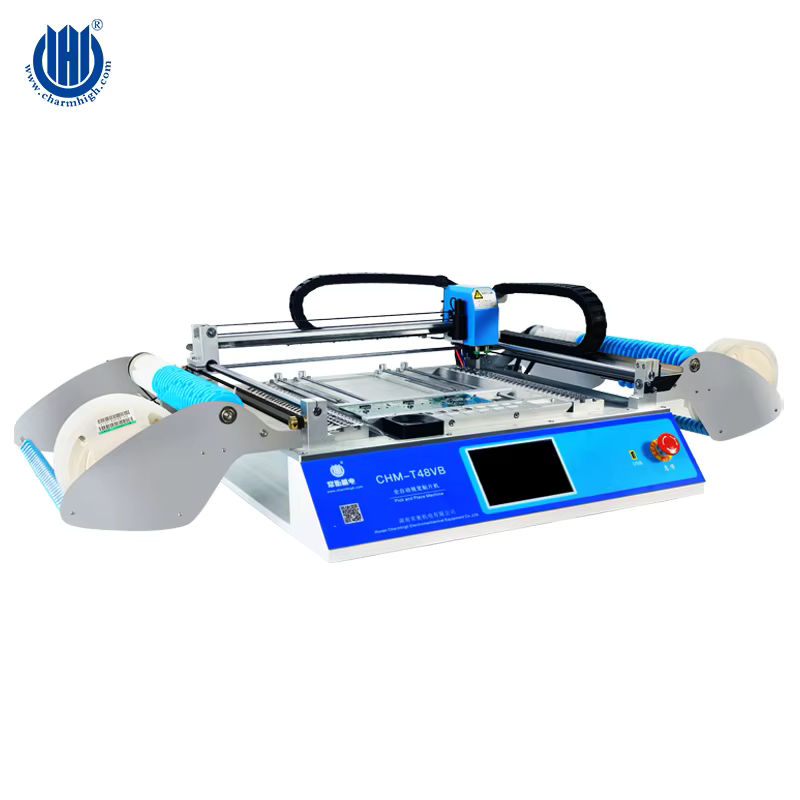

SMT-Pick and Place Machine-TC06 (Small and medium-sized studios)

The TC06 is a high-precision, high-speed 6-head SMT placement machine. With a slim profile of only 90cm in width, it effortlessly fits into elevators, ensuring easy transportation and flexible deployment in factories or studios. Its space-saving design allows for seamless multi-unit integration, delivering efficient mass production capabilities.

- Overview

- Parameter

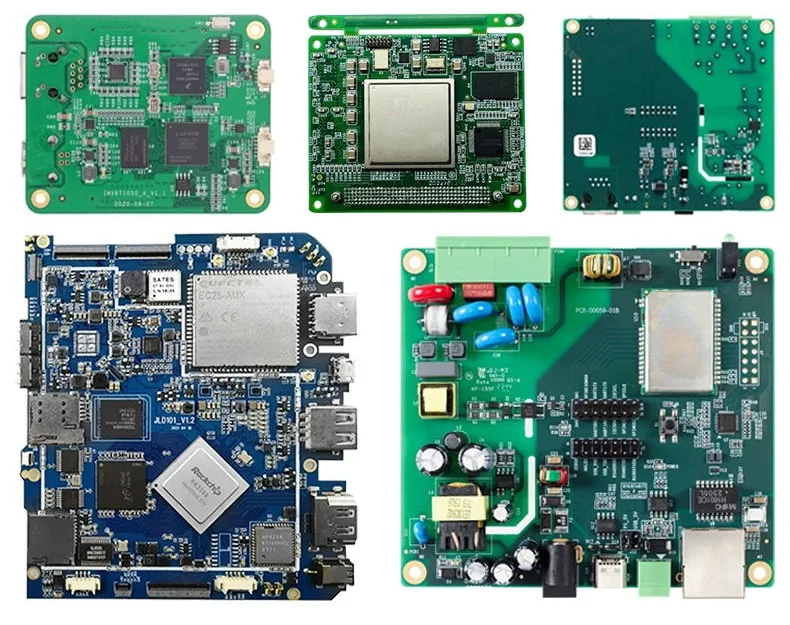

- Recommended Products

|

|

|

ANC

|

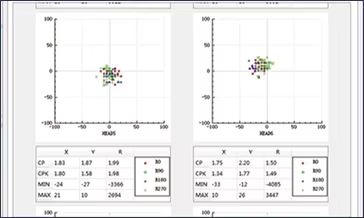

Support CPK |

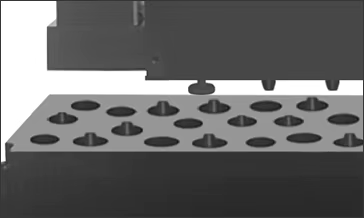

| CPK usually represents the process capability of the pick and place machine.Supporting CPK ensures that the equipment can work stably and accurately within the required range of accuracy. | 19 -hole nozzle library, automatically changes nozzles according to the different components, making your SMT production more intelligent and automatic, and improving production efficiency. |

|

|

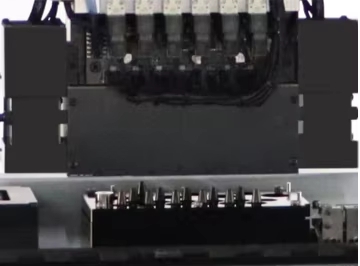

Universal multifunctional mounting head |

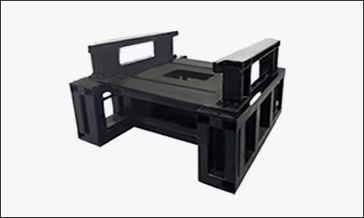

Frame structure |

| Meets the needs of mounting various components and don't need to replace the mounting head. Component mounting range:01005-36mm*36mm. | The grinding platform and the Y-axis gantry are integrally cast. Refuse to use low-cost marble structure, which has poor impact resistance and cannot be repaired if it is damaged one day. |

|

|

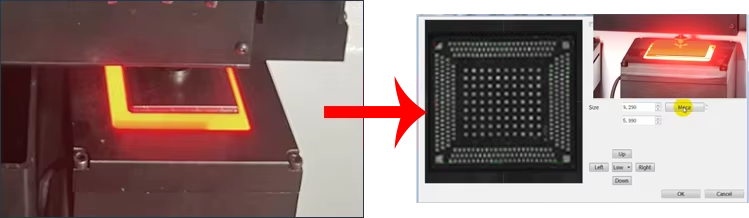

High-definition IC camera vision system |

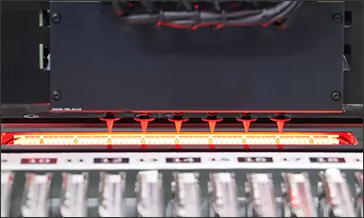

High-speed flying camera |

| Based on advanced visual algorithms, it can clearly identify the number and characteristics of chip pins to ensure high-precision chip mounting. It also has segmentation and recognition functions to ensure the mounting of large components. | High-speed synchronous recognition of components within 16MM*16MM, achieving high-speed mounting.Each nozzle has independent detection function, making SMT production more reliable. |

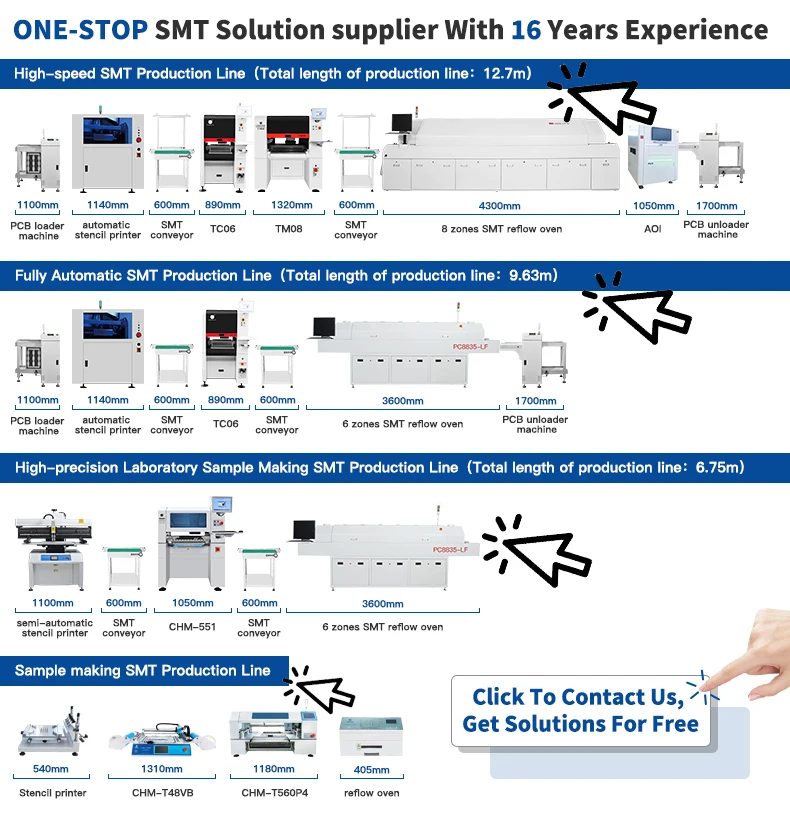

A: Various SMT equipment (such as pick and place machines, solder paste printers, reflow oven) and SMT one-stop services and solutions, professional after-sales service and technical support.

2. Are you a trader or manufacturer?

A:We are a professional pick and place machine manufacturer in China for 15 years.

3. How many days is the delivery date?

A:Normally all our products are in stock and will be shipped within 15 days after payment is received.

4. Why choose us!

China's leading SMT equipment manufacturer, providing professional and timely services.

5. What are the payment terms?

Down payment of 30%, paid before shipment.

TC06 module universal 6 head Pick and Place Machine Specifications

|

TC06 Specifications

|

|

|

Dimensions

|

890mm(L)x1450mm(W)x1500mm(H)

|

|

Weight

|

910kg

|

|

Power Supply

|

AC220V (50Hz, single phase), 3kW

|

|

Air Supply

|

0.5MPa ~0.7MPa

|

|

Vacuum Generation

|

Built-in vacuum pump

|

|

Mounting Head Quantity

|

6

|

|

Mounting Speed

|

27800cph (optimal)

|

|

Mounting Accuracy

|

(xy)±0.04mm CPK≥1.0

|

|

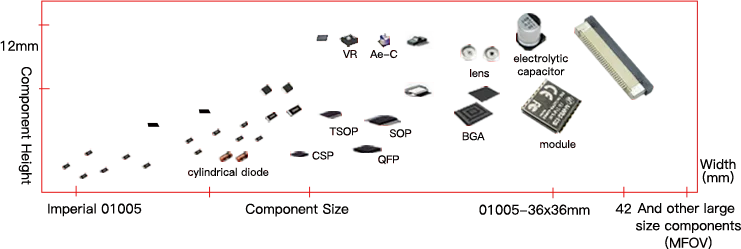

Component Height

|

≤12mm

|

|

Component Type

|

Resistor capacitor exclusion, cylindrical diode, aluminum capacitor, SOT, SOP, QFP, QFN, BGA, etc.

|

|

PCB Thickness

|

0.6mm~3.5mm

|

|

PCB Size

|

350mm(L)x300mm(W)(standard)

|

|

PCB Conveying

|

3-stage buffer transmission

|

|

Nozzle Change

|

Automatic nozzle change (19-hole nozzle library)

|

|

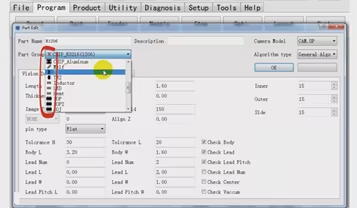

Control System

|

Built-in industrial computer (Windows 7)

equipped with monitor, keyboard, and mouse |

|

Drive System

|

X&Y axis driven by Panasonic servo motor

|

|

Transmission System

|

Ground screws + linear guide

|

|

Feeding System

|

50 NXT 8mm standard feeder stacks

(also suitable for IC tray and stick feeder) |

|

Vision System

|

Fly camera×6 (component size applicable: 16mm×16mm);

IC camera×1 (component size applicable: 36mm×36mm); It has the function of the image stitching,automatic pin and feature recognition Mark camera×2 |