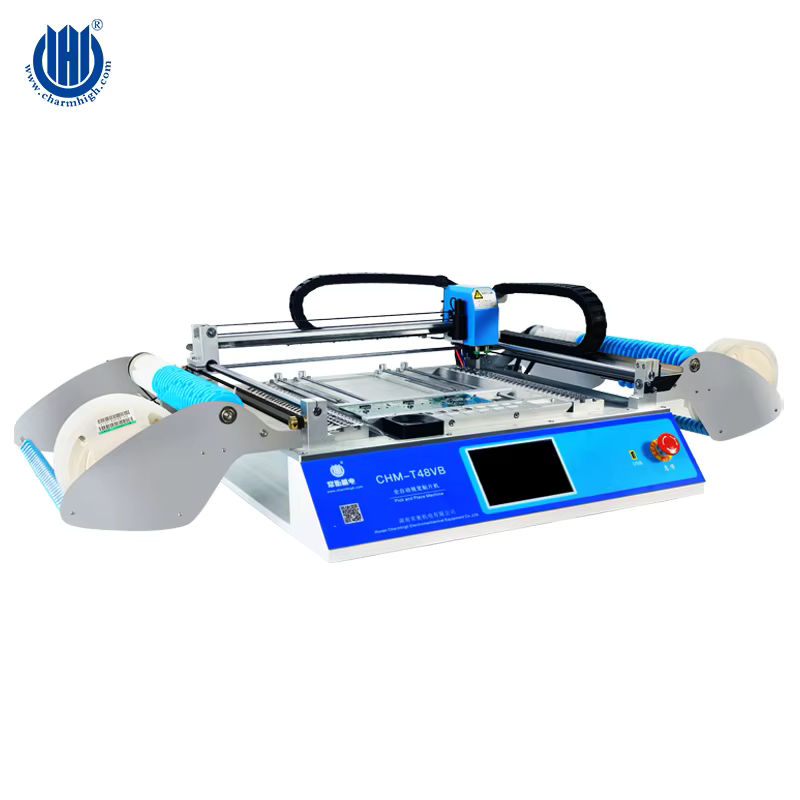

SMT-Pick and Place Machine-CHM-551(PCB design company)

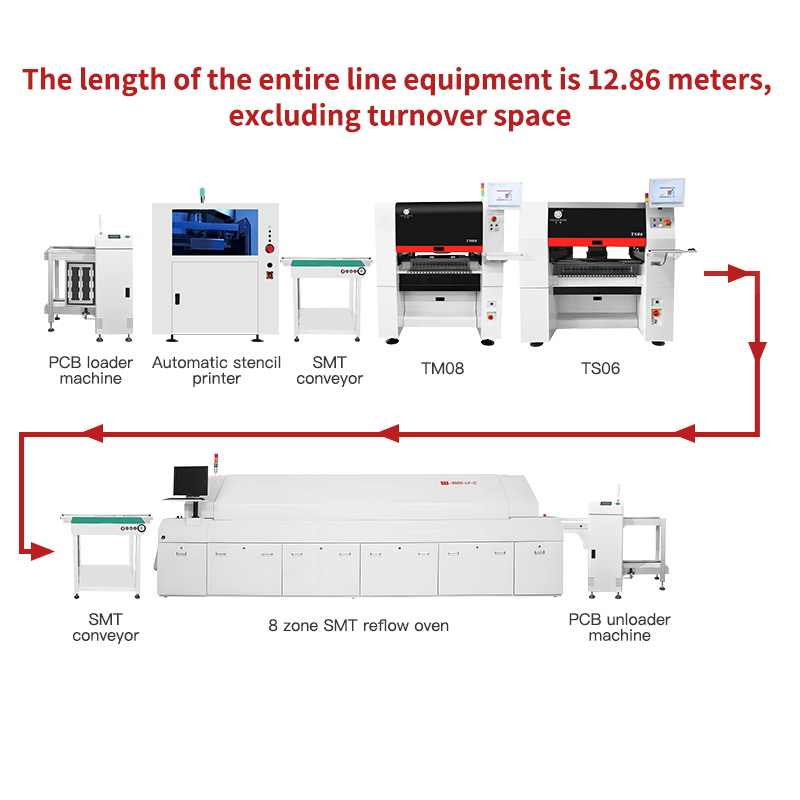

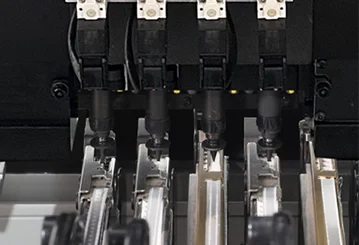

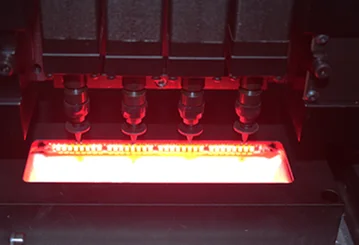

The CHM-551 is a 4-head high-precision SMT pick and place machine, capable of mounting components as small as 0201, making it ideal for small-batch production in factories and PCB prototyping in labs. Equipped with an automatic nozzle changer (ANC) and conveyor system, it streamlines engineering workflows and enhances production efficiency for customers.

- Overview

- Parameter

- Recommended Products

Overview

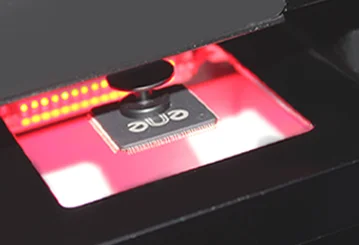

segmentation and recognition functions to ensure the mounting of large components.

A: Various SMT equipment (such as pick and place machines, solder paste printers, reflow oven) and SMT one-stop services and solutions, professional after-sales service and technical support.

2. Are you a trader or manufacturer?

A:We are a professional pick and place machine manufacturer in China for 15 years.

3. How many days is the delivery date?

A:Normally all our products are in stock and will be shipped within 15 days after payment is received.

4. Why choose us!

China's leading SMT equipment manufacturer, providing professional and timely services.

5. What are the payment terms?

Down payment of 30%, paid before shipment.

CHM-551 Small, high precision 4 head Pick and Place Machine Specifications

|

CHM-551Specifications

|

|

|

Dimensions

|

1050mm(L)X 1050mm(W) X 885mm(H)

|

|

Weight

|

190kg

|

|

Power Supply

|

AC220V (50Hz,single phase) 600W

|

|

Air Supply

|

0.5MPa ~0.7MPa

|

|

Vacuum Generation

|

Vacuum generator (Japan PISCO)

|

|

Mounting Head Quantity

|

4

|

|

Mounting Speed

|

11500cph (optimal)

IPC9850 speed:8850cph |

|

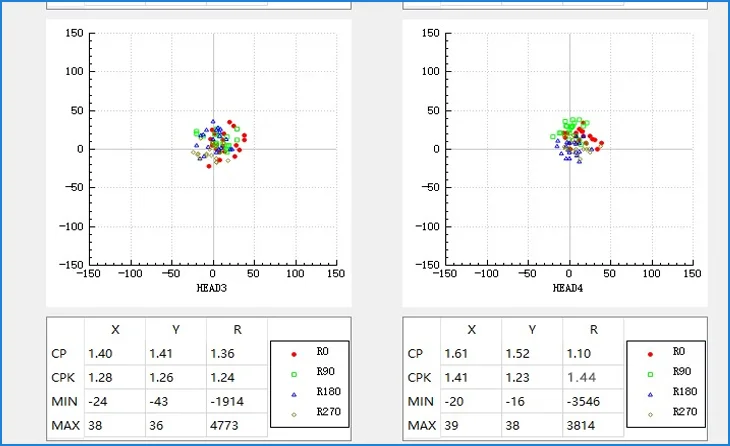

Mounting Accuracy

|

±60μm CPK≥1.0(XY)

|

|

Control Accuracy

|

5μm

|

|

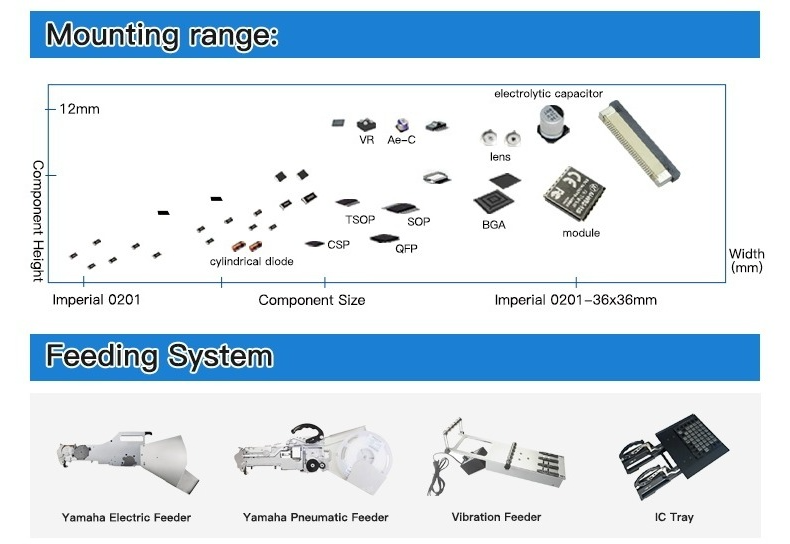

Component Height

|

12mm

|

|

Component Type

|

0201/0402/0603~5050/SOT/SOP/QFP/QFN/BGA, etc.

(resistor/capacitor/diode/triode/LED/IC, etc.) |

|

PCB Thickness

|

0.6mm~3.5mm

|

|

PCB Size

|

350mm(L)×270mm(W) (standard);

600mm(L)×270mm(W) (optional) |

|

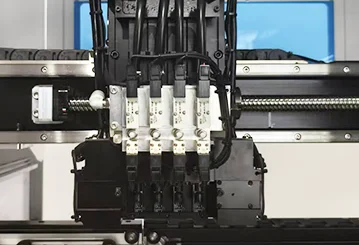

Nozzle Change

|

Automatic nozzle change (13 hole nozzle library)

|

|

Control System

|

Built-in industrial computer (Linux operating system)

equipped with monitor, keyboard, and mouse |

|

Drive System

|

X&Y axis driven by servo motors;adopting flexible S-curve acceleration and deceleration

|

|

Transmission System

|

Ball screw + linear guide,automatic transfer rail system

|

|

Feeding System

|

50 Yamaha 8mm standard pneumatic/electric feeder stacks

(also suitable for IC tray and stick feeder) |

|

Vision System

|

Snapshot camera×4 (component size applicable: 14mm×14mm);

IC camera×1 (component size applicable: 36mm×36mm); Mark camera×2 |

|

Vision System

|

Fly camera×6 (component size applicable: 16mm×16mm);

IC camera×1 (component size applicable: 36mm×36mm) Mark camera×2 |