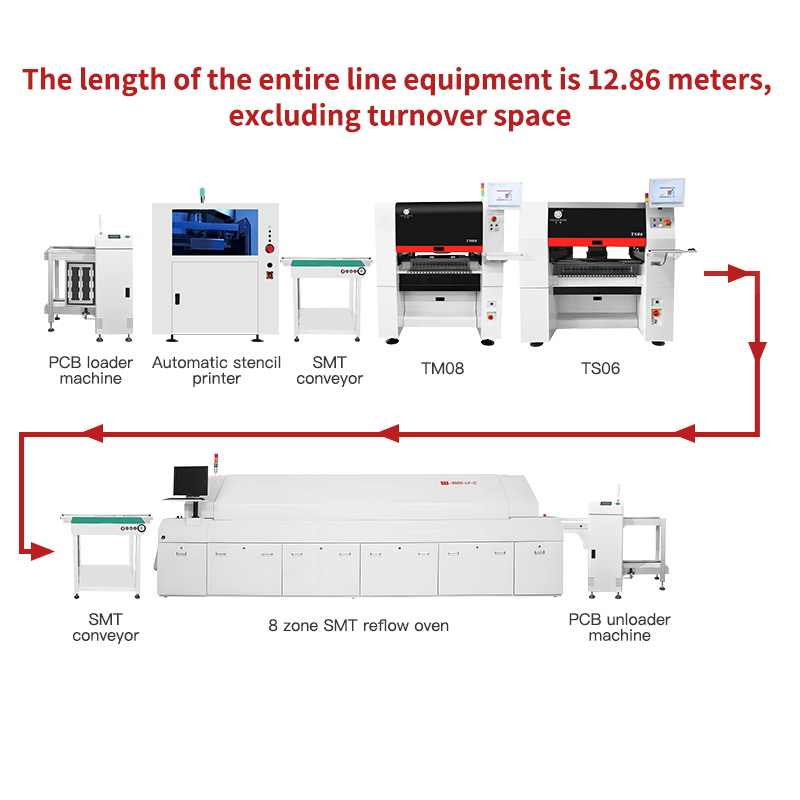

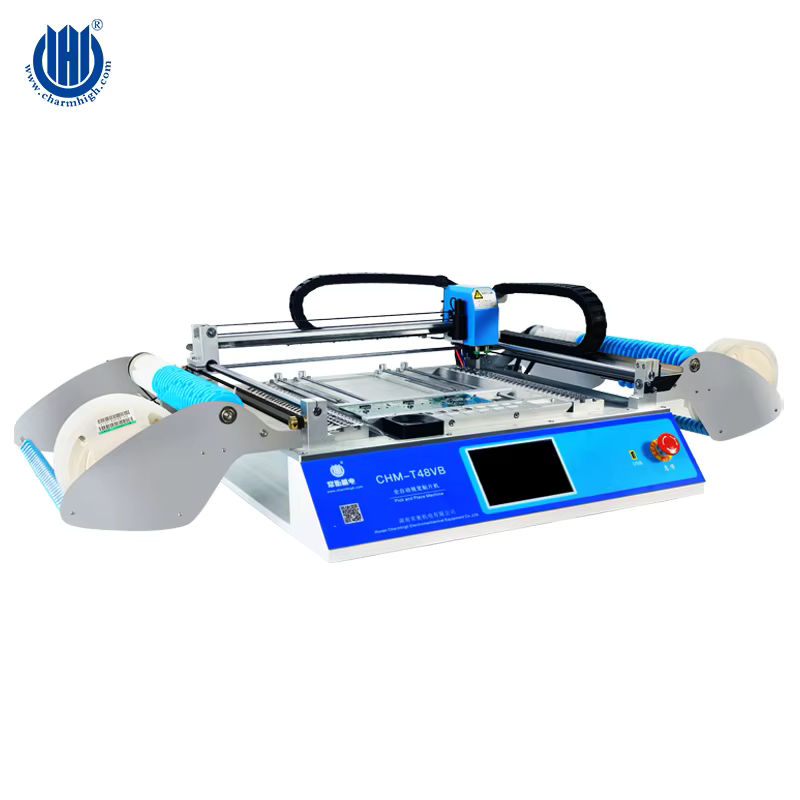

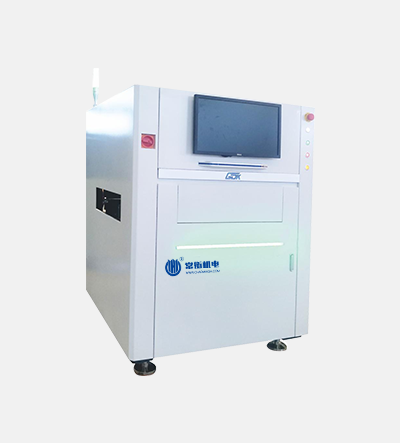

TM08 Manufacturer Electronics Production Machinery Pcb Exposure Pick and Place Motherboard Machine

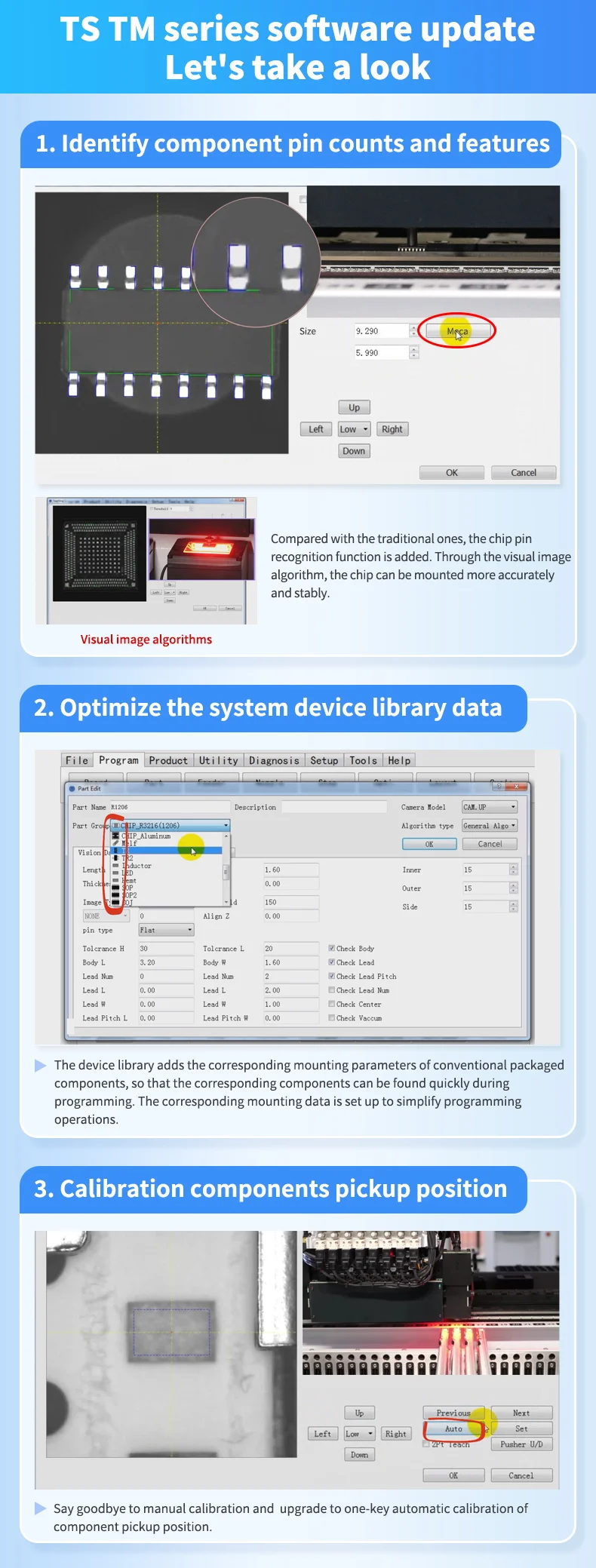

capable of mounting 01005 components, also supporting large-size component segmentation and recognition, covering all sizes.

- Overview

- Parameter

- Recommended Products

Overview

|

|

| PCB load machine | PCB Unload machine |

Automatically transports PCB boards to the production line, and automatically and accurately delivers PCB boards to the next device by receiving the board request signal from the lower computer. |

Used to collect processed PCB boards, usually at the end of the SMT production line. |

|

|

| Solder paste printing machine | Multi-function universal pick and place machine |

The working principle is to fix the PCB on the printing table, then use a scraper to print the solder paste through the steel mesh on the designated pad, and then transfer it to the pick and place machine through the track. |

By importing the PCB coordinate file, locating the PCB origin and the material picking position, the surface mount components are accurately mounted on the PCB board through the nozzle of the mounting head. |

|

|

| SMT Conveyor | AOI |

| Used to connect devices in SMT production lines, with transmission and board stopping functions. | Automatic optical inspection uses high-speed and high-precision visual processing technology to automatically detect various mounting errors and welding defects on PCB boards. |

|

|

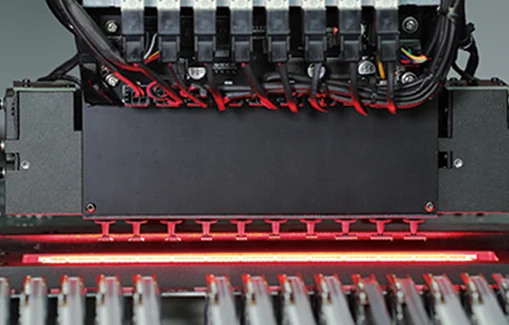

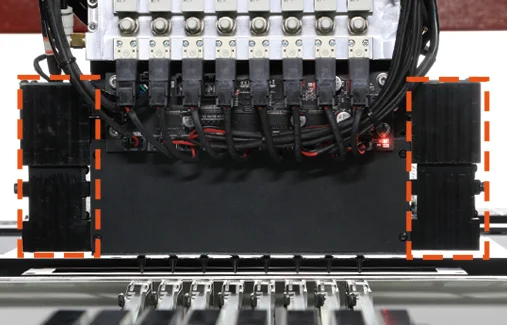

| 8- zone reflow oven | Feeder |

The solder paste is melted by heating to connect the components to the PCB boards, and then solidified by cooling. It is divided into preheating zone- constant temperature zone reflow zone - cooling zone. |

Tape feeder, tube feeder, tray feeder. Used for feeding packaged components on SMT machine |

A: Various SMT equipment (such as pick and place machines, solder paste printers, reflow oven) and SMT one-stop services and solutions, professional after-sales service and technical support.

2. Are you a trader or manufacturer?

A:We are a professional pick and place machine manufacturer in China for 15 years.

3. How many days is the delivery date?

A:Normally all our products are in stock and will be shipped within 15 days after payment is received.

4. Why choose us!

China's leading SMT equipment manufacturer, providing professional and timely services.

5. What are the payment terms?

Down payment of 30%, paid before shipment.

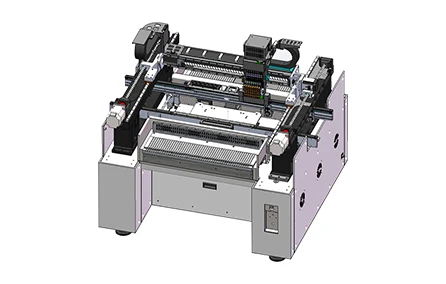

TM08 High speed, high precision and multi-function 8 head

|

TM08 Specifications

|

|

|

Dimensions

|

1280mm(L)×1580mm(W)×1500mm(H)

|

|

Weight

|

1450kg

|

|

Power Supply

|

AC220V (50Hz, single phase), 3.5kW

|

|

Air Supply

|

0.5MPa ~0.7MPa

|

|

Vacuum Generation

|

Built-in vacuum pump

|

|

Mounting Head Quantity

|

8

|

|

Mounting Speed

|

35000cph (optimal)

|

|

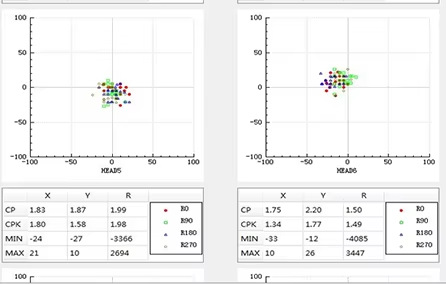

Mounting Accuracy

|

(XY)±0.035mm CPK≥1.0

|

|

Component Height

|

≤12mm

|

|

Component Type

|

01005/0201/0402/0603~5050/SOT/SOP/QFP/QFN/BGA, etc.(resistor/capacitor/diode/triode/LED/IC, etc.)

|

|

PCB Thickness

|

0.6mm~3.5mm

|

|

PCB Size

|

450mm(L)×350mm(W) (standard);

1200mm(L)×350mm(W) (optional) |

|

PCB Conveying

|

3-section-rail automatic conveying, PCB support device

|

|

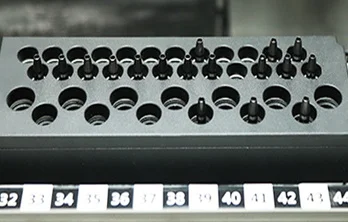

Nozzle Change

|

Automatic nozzle change (31-hole nozzle library)

|

|

Control System

|

Built-in industrial computer (Windows 7)

equipped with monitor, keyboard, and mouse |

|

Drive System

|

X&Y axis driven by Panasonic A6 servo motors (Y axis by double motors); adopting flexible S-curve acceleration and deceleration

|

|

Transmission System

|

X&Y axis adopting ground screw and mute linear guide

(Y axis with double screws) |

|

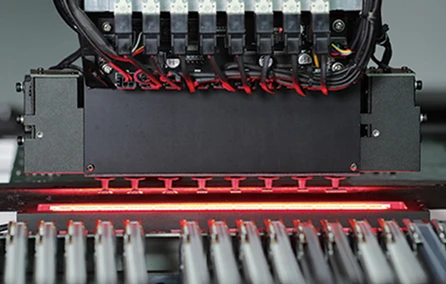

Feeding System

|

80 NXT 8mm standard feeder stacks

(also suitable for IC tray and stick feeder) |

|

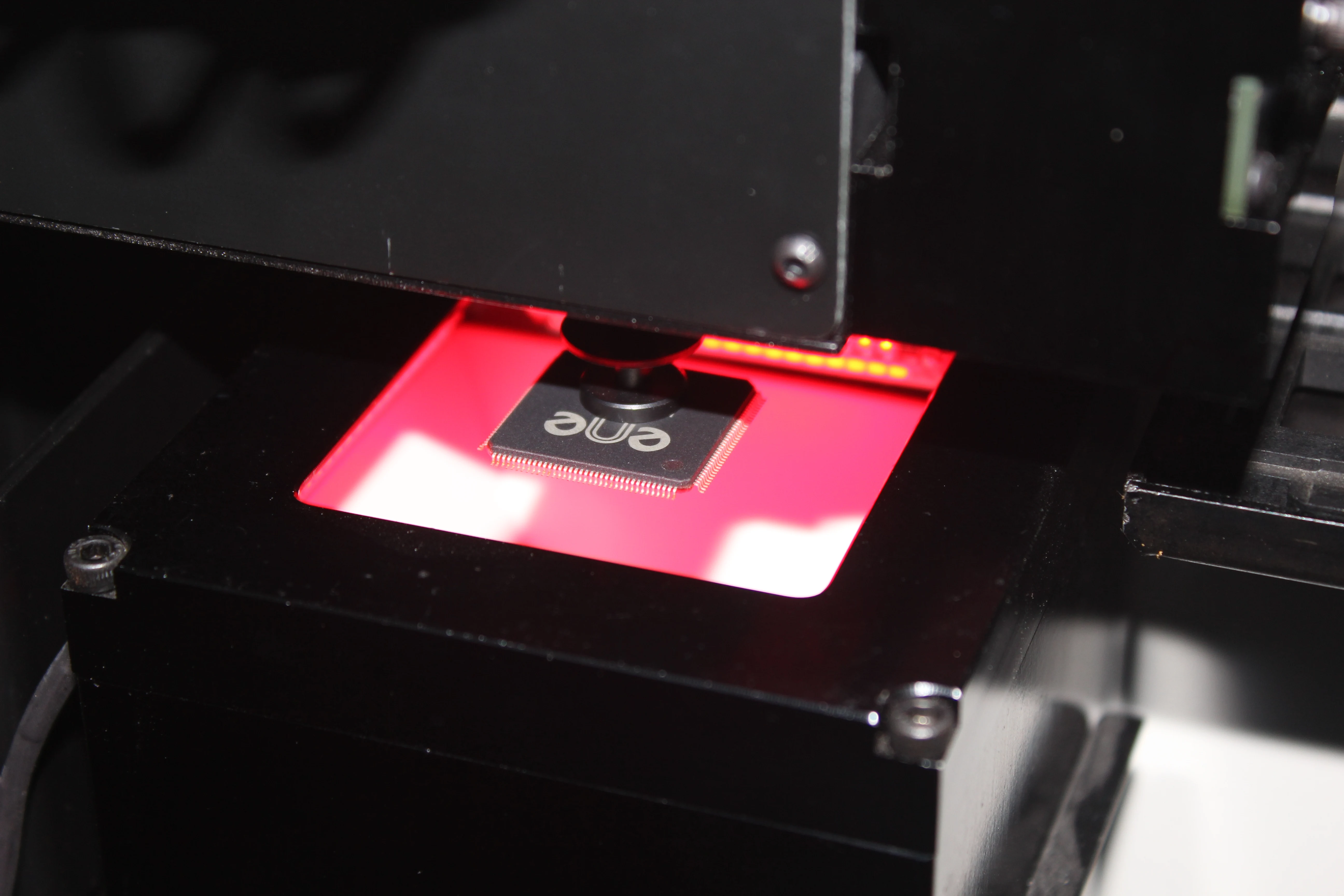

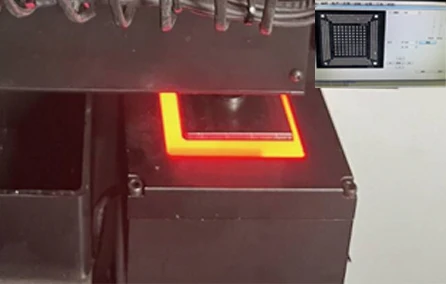

Vision System

|

Fly camera×8 (component size applicable: 16mm×16mm);

IC camera×1 (component size applicable: 36mm×36mm); Mark camera×2 |