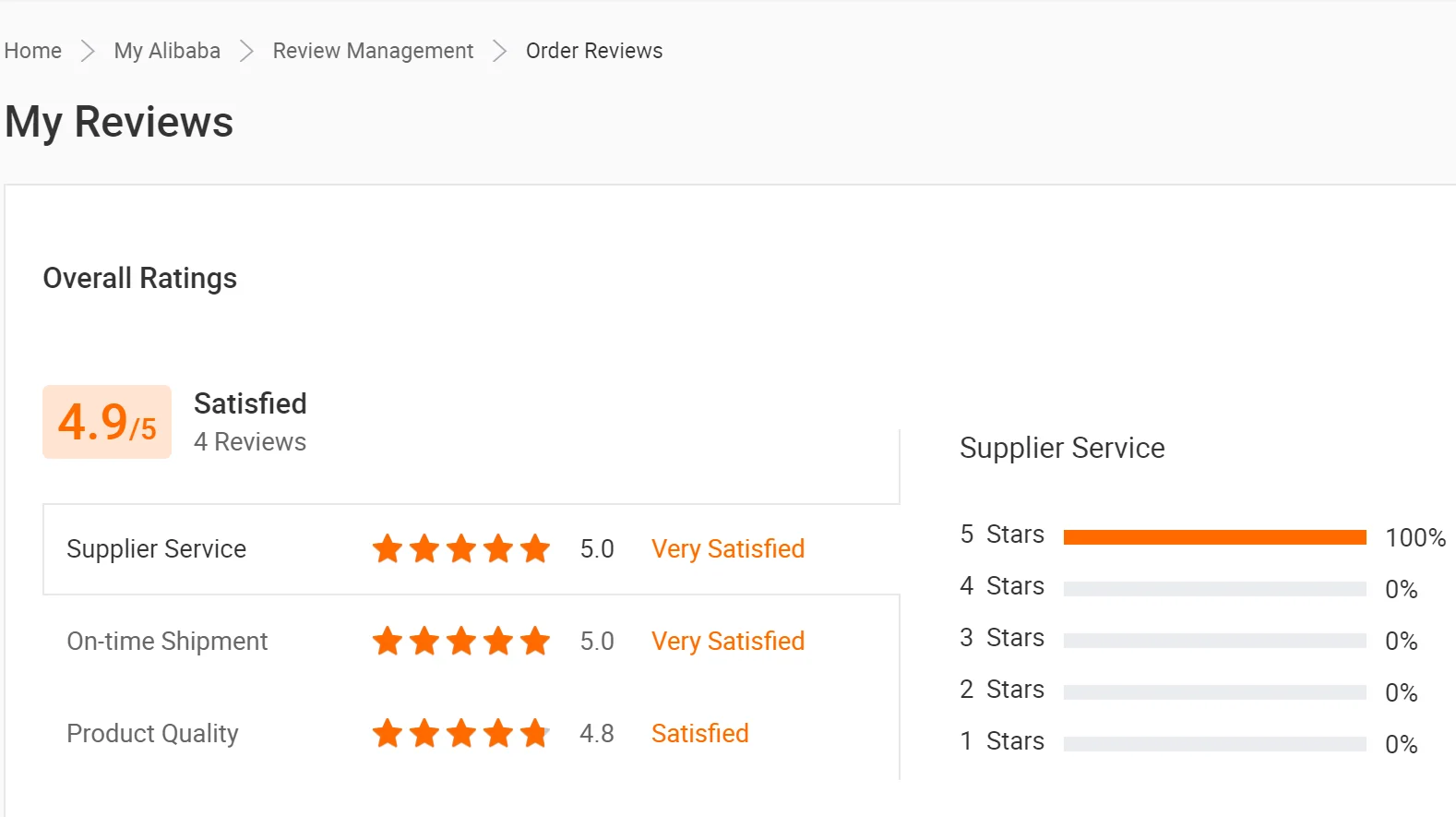

ZD-400 SOLDER PASTE MIXER for PICK and PLACE MACHINE PRODUCTION LINE

ZD-400 solder paste mixer for SMT production lines. Ensures uniform paste consistency, improving soldering quality and efficiency for pick-and-place machine operations.

- Overview

- Parameter

- Recommended Products

ZD-400 SOLDER PASTE MIXER

Machine features & functions:

1.0 Maximum speed up to 1000 RPM

1.1 When stirring, the tin paste should be deiced beforehand;

1.2 You don't have to open the container;

1.3 Power supply single phase 220v:

1.4 No moisture problem:

1.5 It does not destroy the shape of the tin powder:

1.6 The fixture is suitable for all kinds of 500g packaging tin paste cans;

1.7 Stirring time can be set arbitrarily;

Solder paste mixer installation and commissioning:

2.1 Install

2.1.1 Please place the machine on a horizontal and stable table or ground, and adjust the four foot cups of the machine to level to avoid abnormal sound or shaking when the machine is stirring at high speed.

2.1.2 Please check the service voltage specification of the machine (Ac220v) should be consistent with the voltage specification of the mains, and connect the single-phase 220V power supply.

2.1.3 Please confirm whether there is any screw loose, no foreign body in the machine plate, to avoid collision

2.2 Debug

2.2.1 Make sure the machine is placed smoothly.

2.2.2 Place the tin paste cans to be stirred completely in the machine fixture and stir two 500G tin paste cans at the same time.

2.2.3 Please turn the tin paste pot once by hand to make sure there is no collision, put the lid on the machine and turn on the power switch.

2.2.4 Adjust the panel time and set it to a better mixing time, about 35 minutes, depending on the brand of solder paste and the situation at that time.

2.2.5 After pressing the start switch, the operation indicator will light up and the machine will start to stir automatically at high speed until the machine will stop automatically and the power will be cut off automatically when the cover is opened.

2.2.6 After the operation is completed, the operation stops and the actual stirring time is displayed on the screen.

2.2.7 If you want to stop the machine during operation, press the power switch to stop and cancel the operation.

Operation procedure and matters needing attention of solder paste mixer

3.1.0 After debugging, open the top cover of the machine to confirm that there is no foreign matter in the machine.

3.1.1 Turn the Angle of the machine solder paste fixture and place the solder paste can to be stirred into the machine fixture.

3.1.2 Please turn the tin paste pot once by hand to make sure there is no collision, close the top cover of the machine, and turn on the power switch.

3.1.3 Adjust the time switch on the panel to set the best mixing time, depending on the solder paste brand.

3.1.4 After pressing the start switch, the operation indicator will light up and the machine will automatically stir at high speed until the machine stops automatically.

3.1.5 After the operation is completed, the operation stops and the actual mixing time is displayed on the screen. After the machine stops running, open the upper cover and remove the solder paste pot on the fixture. At this time, the solder paste softened by temperature return and evenly stirred can be used.

3.1.6 If you want to stop the machine during operation, press the power switch to stop and cancel the operation.

3.1.7 Open the top cover of the machine during operation, and the machine will stop running automatically. If you want to continue the stirring operation after the top cover is closed, you need to press the start switch again.

3.1.8 When the production quantity is finished, turn off the power switch;

3.2.0 If you want to open the upper cover of the machine after the production runs, you must wait for the machine to stop completely before opening it:

3.2.1 The weight difference of the solder paste tank or weight distributor on the left and right fixtures should not exceed 100 grams, otherwise, the machine will shake when mixing at high speed, please try to avoid it;

Regular inspection and maintenance of solder paste mixer

1, Please keep the machine clean;

2, Check whether the screws are loose;

3,Check machine switch and upper cover matching sensitivity before operation;

4,The bearing of this machine is fully enclosed without lubricating oil.

Solder paste mixer machine specifications

1,Operating voltage of solder paste mixer:AC 220V 50Hz 60Hz 60W

2,Operation speed of solder paste mixer:Motor 1350 RPM revolution:1000RPM

rotation:500PRM

3,Working ability of solder paste mixer:500. Such as needle tube red rubber tube, fixture can be customized

4,Stir two POTS of paste at the same time:500g

5,Solder paste mixer mixing time:1 99 minutes digital adjustable

6,Operation mode of solder paste mixer: easy to operate with light touch button

7,Solder paste mixer fixture function: general use fixture, suitable for various brands of solder paste cans

8,Operation noise of solder paste mixer: low operation noise < 20dB

The machine size

400x400x420mm Weight:35KG

Description of parameters and operation panel

Key function and time setting:

Why choose us:

Thanks & best regards

Ellen Meng

Hunan Charmhigh Electromechanical Equipment Co., Ltd.

Add.:104-604,Building D,Jingrong Tongxin International Industrial Park(jindao Park),NO 179 ,Huizhi Middle Road,HI-TECH Development Zone,Changsha ,Hunan,P.R.China

Tel:0086-731-85504084 Fax:0086-731-85504064 Cell/wechat/whatsapp/skype:0086-18974948067

Machine parameters

|

model No. |

ZD-400 |

|

running speed |

motor speed:1350RPM; a revolution 1000RPM; the second rotation :500RPM |

|

working ability |

0-1000G*2 CANS |

|

Can accept tin paste cans |

apply to 500G tin solder paste can |

|

time setting |

0.1-9.9minutes,Adjust for 0.1 minutes each time; 10-30minutes,Adjust for 10 minutes each time |

|

Display mode |

LED digital display |

|

motor |

1350/min |

|

working power supply |

220V 50/60HZ >60W |

|

dimension |

400mm*400mm*420mm |

|

machine weight |

35KG |