8 Zone Reflow Oven up 8 + Bottom 8 Computer-controlled SMT Production Line Equipment F840

8-zone computer-controlled reflow oven for efficient SMT production. Ensures precise, uniform soldering for various PCB assemblies, suitable for small to large-scale electronics manufacturing.

- Overview

- Parameter

- Recommended Products

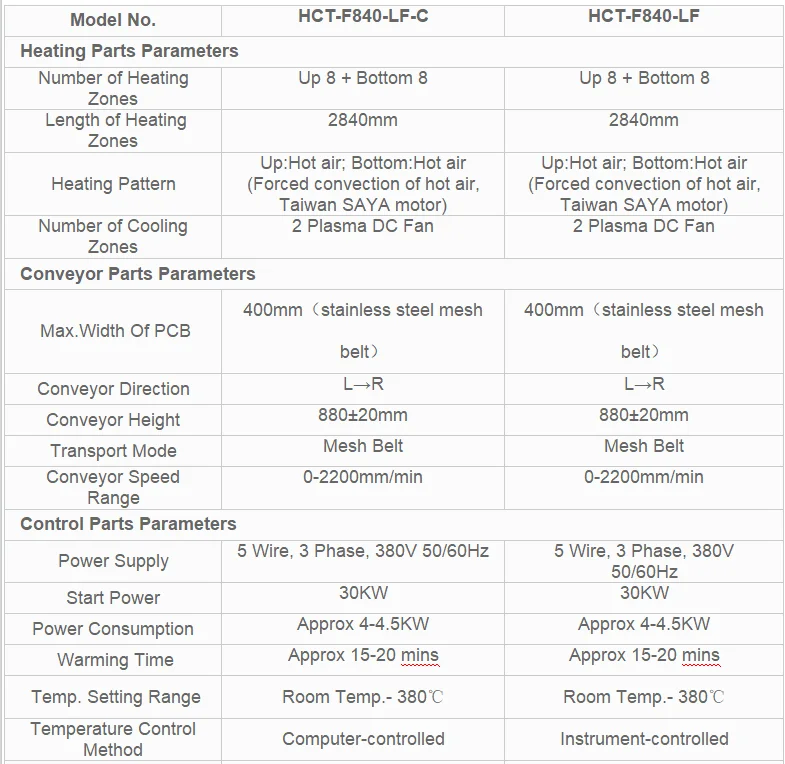

Specification

|

Model No.

|

HCT-F840-LF-C

|

HCT-F840-LF

|

|

Heating Parts Parameters

|

||

|

Number of Heating Zones

|

Up 8 + Bottom 8

|

Up 8 + Bottom 8

|

|

Length of Heating Zones

|

2840mm

|

2840mm

|

|

Heating Pattern

|

Up:Hot air; Bottom:Hot air

(Forced convection of hot air, Taiwan SAYA motor) |

Up:Hot air; Bottom:Hot air

(Forced convection of hot air, Taiwan SAYA motor) |

|

Number of Cooling Zones

|

2 Plasma DC Fan

|

2 Plasma DC Fan

|

|

Conveyor Parts Parameters

|

||

|

Max.Width Of PCB

|

400mm(stainless steel mesh belt)

|

400mm(stainless steel mesh belt)

|

|

Conveyor Direction

|

L→R

|

L→R

|

|

Conveyor Height

|

880±20mm

|

880±20mm

|

|

Transport Mode

|

Mesh Belt

|

Mesh Belt

|

|

Conveyor Speed Range

|

0-2200mm/min

|

0-2200mm/min

|

|

Control Parts Parameters

|

||

|

Power Supply

|

5 Wire, 3 Phase, 380V 50/60Hz

|

5 Wire, 3 Phase, 380V 50/60Hz

|

|

Start Power

|

30KW

|

30KW

|

|

Power Consumption

|

Approx 4-4.5KW

|

Approx 4-4.5KW

|

|

Warming Time

|

Approx 15-20 mins

|

Approx 15-20 mins

|

|

Temp. Setting Range

|

Room Temp.- 380℃

|

Room Temp.- 380℃

|

|

Temperature Control Method

|

Computer-controlled

|

Instrument-controlled

|

|

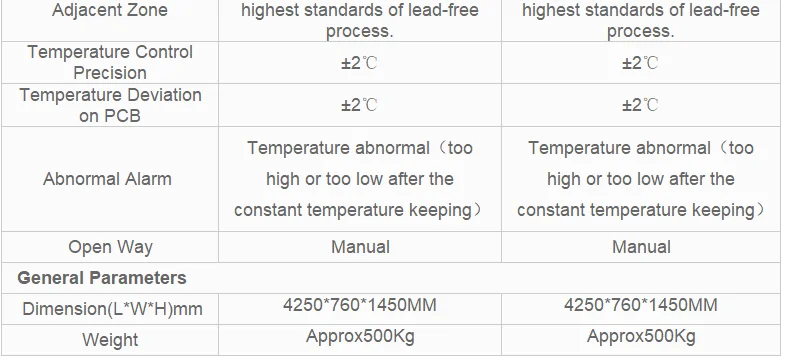

Temperature Difference Between Adjacent Zone

|

70 ℃, can correspond to the highest standards of lead-free process.

|

70 ℃, can correspond to the highest standards of lead-free process.

|

|

Temperature Control Precision

|

±2℃

|

±2℃

|

|

Temperature Deviation on PCB

|

±2℃

|

±2℃

|

|

Abnormal Alarm

|

Temperature abnormal(too high or too low after the constant temperature keeping)

|

Temperature abnormal(too high or too low after the constant temperature keeping)

|

|

Open Way

|

Manual

|

Manual

|

|

General Parameters

|

||

|

Dimension(L*W*H)mm

|

4250*760*1450MM

|

4250*760*1450MM

|

|

Weight

|

Approx500Kg

|

Approx500Kg

|