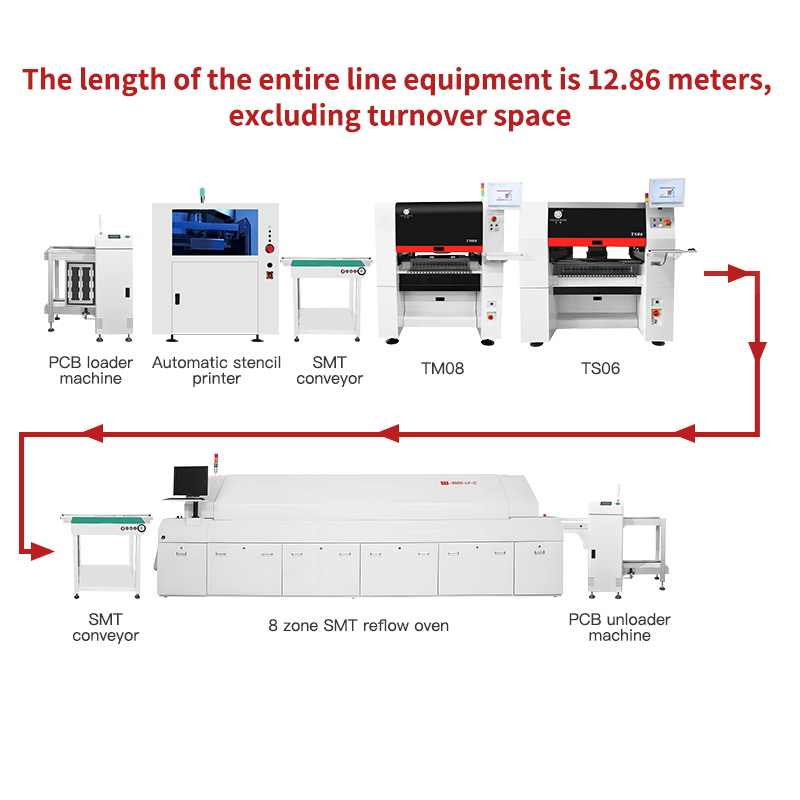

Charmhigh TM06 Automatic Pick and Place Machine SMT 6 Head Machine LED PCB Assembly SMD Pick and and Place Machine for SMT Producitin

capable of mounting 01005 components, also supporting large-size component segmentation and recognition, covering all sizes.

- Overview

- Parameter

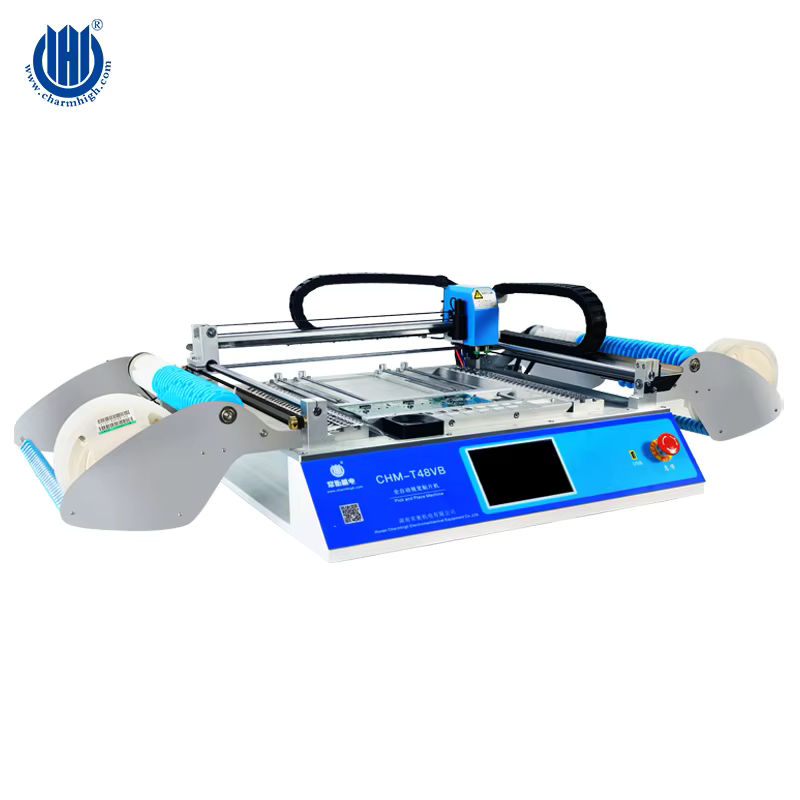

- Recommended Products

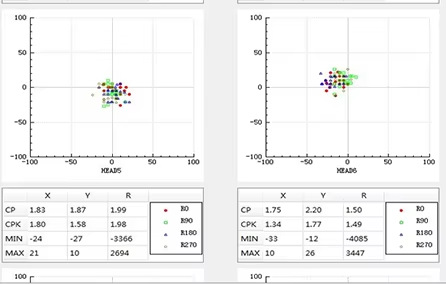

TS06 Specifications | ||||||||||||||||||||||||||||||||||||||

|

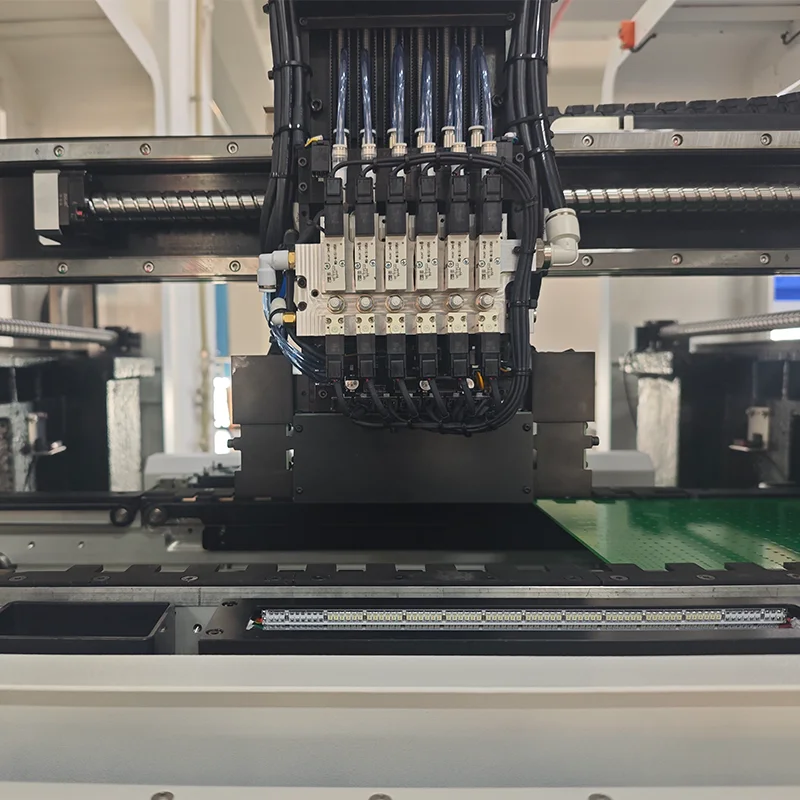

TM06 High speed, high precision and multi-function 6 head Pick and Place Machine Specifications

|

TS06 Specifications

|

||||||||||||||||||||||||||||||||||||||

|