Understanding SMT Pick and Place Machine Types and Production Fit Manual vs. Semi-Automatic vs. Fully Automatic SMT Pick and Place Machines Pick and place machines used in Surface Mount Technology come in three main categories depending on how auto...

VIEW MORE

The Miniaturization Challenge in Modern About SMT Equipment Trends Driving Component Miniaturization in Electronics Manufacturing Consumer demand for lighter wearables, IoT sensors, and ultra-thin devices has reduced component sizes by 56% since 201...

VIEW MORE

Speed, Throughput, and Production Volume Alignment About SMT Pick and Place Machine Understanding speed metrics: CPH and cycle time When talking about SMT pick and place machines, there are basically two main things that determine how well they perf...

VIEW MORE

The Importance of SMT Production in Automotive Electronics How SMT Technology Supports Modern Automotive Electronics Surface Mount Tech, or SMT for short, makes it possible to shrink down parts and boost reliability in modern car tech like those fan...

VIEW MORE

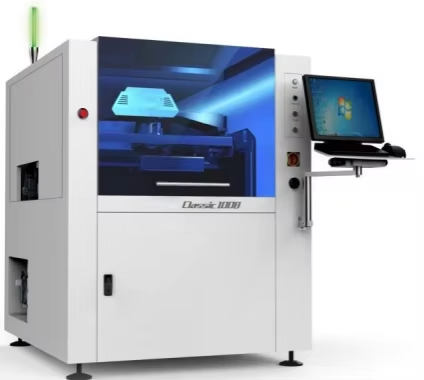

Understanding SMT Line Configuration and Core Integration Principles The Growing Complexity of SMT Line Setup in Modern Electronics Manufacturing Manufacturers are seeing a big change in their SMT line needs as they move towards producing many diffe...

VIEW MORE

Precision Engineering: The Role of Accuracy in High-End SMT Pick and Place Machines Understanding Placement Accuracy and Its Impact on PCB Assembly Quality Getting the placement right on SMT pick and place machines means components land within abou...

VIEW MORE

Understanding SMT Machine Impact on Factory Efficiency and Cost How SMT machine selection affects production efficiency and cost-effectiveness SMT machinery forms the core of today's electronics manufacturing operations, and what kind of equipment g...

VIEW MORE

SMT Machine Setup and Calibration: Laying the Foundation Successful SMT machine operation begins with initial alignment and level calibration of the production line, where even a 0.1° tilt in conveyor rails can reduce placement accuracy by up t...

VIEW MORE

Choosing the Wrong SMT Pick and Place Machine Type for Your Production Needs Understanding the difference between chip shooter and odd-form SMT pick and place machines Chip shooter SMT machines excel at placing those tiny standard parts like resist...

VIEW MORE

Understanding the Role of SMT Pick and Place Machines in Modern Electronics Manufacturing Understanding automated component placement in SMT and its impact on PCB assembly The introduction of automated component placement via Surface Mount Technolog...

VIEW MORE

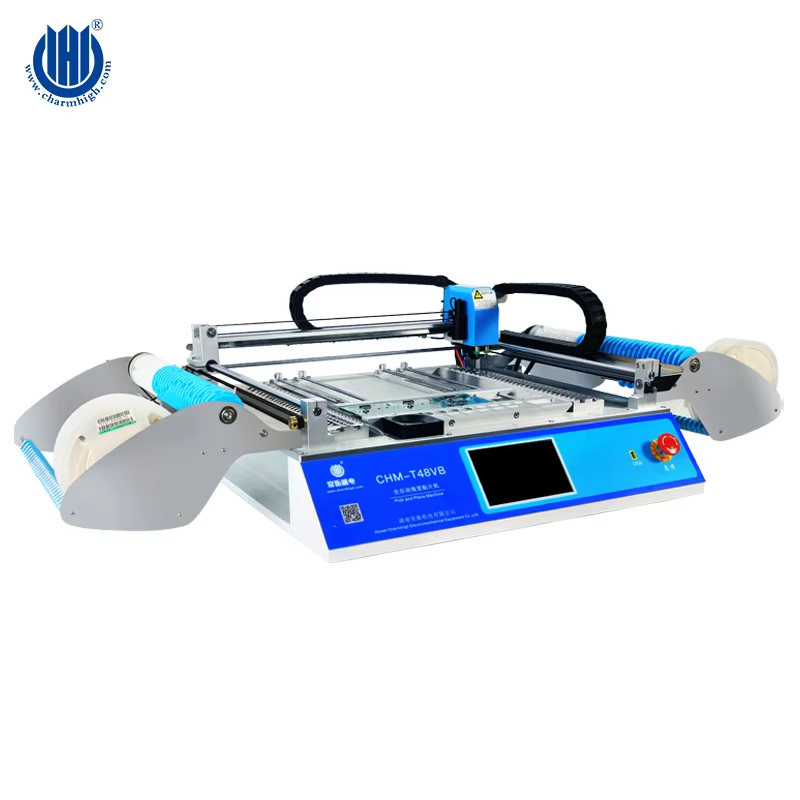

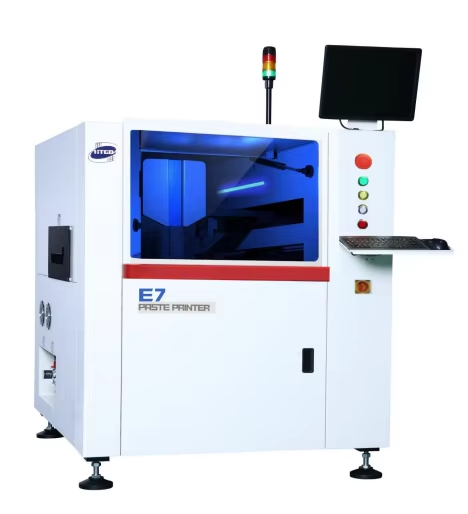

Understanding SMT Pick and Place Machine Fundamentals What Is an SMT Pick and Place Machine? The SMT (Surface Mount Technology) pick and place machine is basically what makes it possible to put tiny electronic components on those printed circuit boa...

VIEW MORE

How to Increase PCB Assembly Efficiency with an SMT Pick and Place Machine Surface-mount technology (SMT) has revolutionized electronics assembly allowing components to be placed directly on PCBs without drilling holes. This departure from through-h...

VIEW MORE