Speed, Throughput, and Production Volume Alignment About SMT Pick and Place Machine

Understanding speed metrics: CPH and cycle time

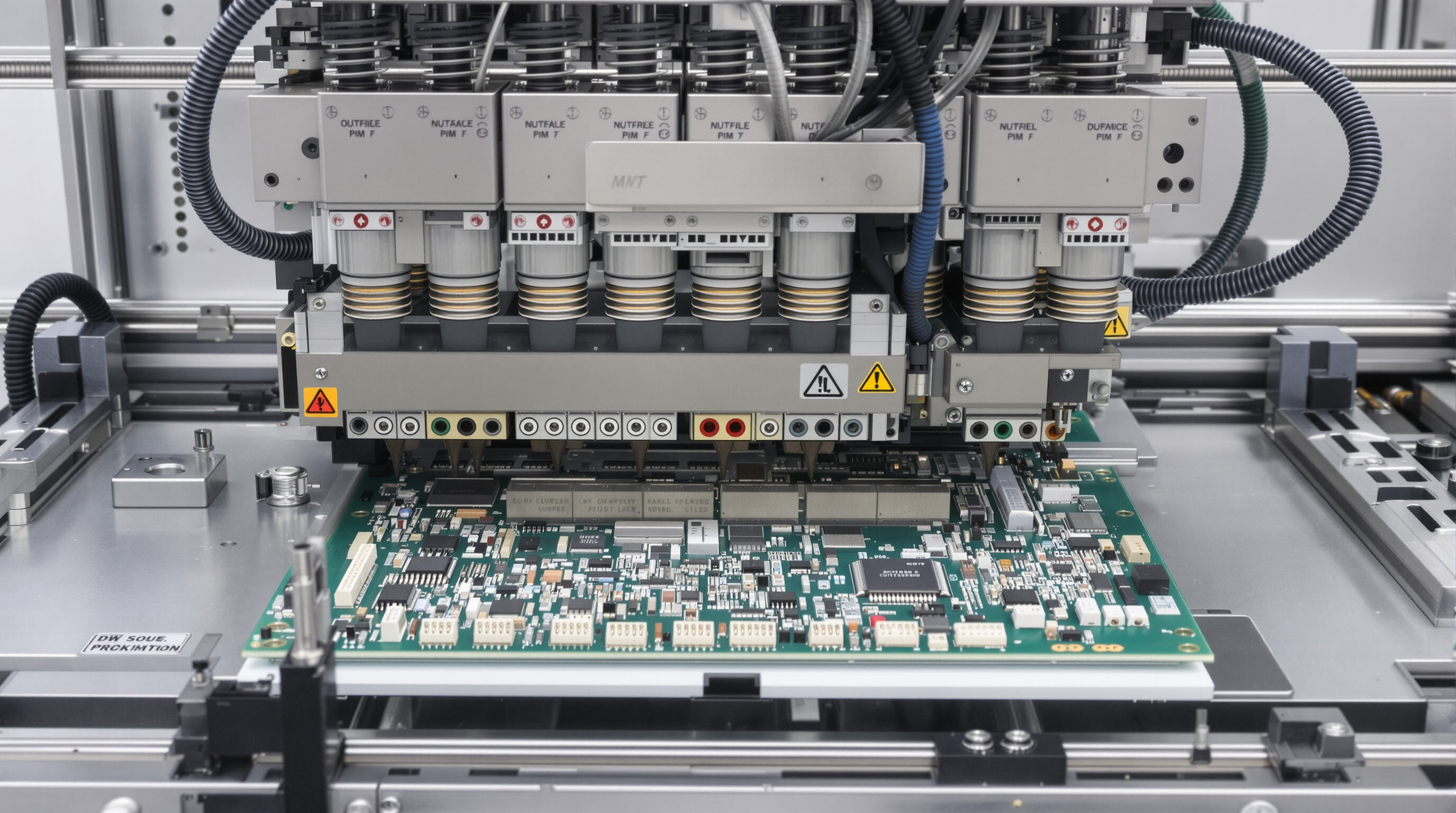

When talking about SMT pick and place machines, there are basically two main things that determine how well they perform: Components Per Hour (CPH) and what we call cycle time. The CPH number tells us roughly how many components the machine could theoretically put down in an hour if everything was perfect, which obviously never happens in real life. Cycle time on the other hand shows just how fast the machine actually moves from one placement to the next. Take a machine that's advertised as doing 24,000 CPH for example. That would mean placing something every 0.15 seconds in theory. But when we look at actual production floors, things get complicated. Factors such as the complexity of the PCB board being worked on and how the feeders are set up usually bring down the real performance somewhere between 15% to maybe even 30% below those impressive spec sheet numbers.

Matching machine speed with your production volume requirements

Getting the right balance between machine speed and what the factory actually needs is key to avoiding money draining inefficiencies in production. For smaller shops making less than 5,000 printed circuit boards each month, equipment that handles around 8,000 to 12,000 circuits per hour works best when combined with quick setup times for different jobs. Big manufacturers cranking out over 50,000 PCBs monthly need serious hardware capable of pushing past 30,000 CPH, usually with those fancy automatic feeder towers that keep everything running smoothly. Companies sitting in the middle ground somewhere? They'd be wise to invest in modular setups first. These kinds of machines let businesses scale up gradually as customer orders grow instead of buying expensive new equipment every time demand spikes unexpectedly.

Trade-offs between high-speed placement and precision

When manufacturers try to boost placement speeds, they usually end up losing some accuracy along the way. Every time there's a 10% increase in speed, positioning gets worse by around 3 to 5 microns because of all the extra mechanical vibrations plus shorter inspection times for the vision systems. This matters a lot when dealing with delicate parts like those tiny 0201 passive components that need to stay within +/-25 micron tolerance. To keep things accurate while still moving fast enough, equipment needs special stabilization tech. Things like having two motors driving both X and Y axes separately, plus systems that actively dampen vibrations as they happen make all the difference. These features help maintain quality standards even at higher production rates.

Case study: Optimizing throughput in mid-volume PCB assembly

A mid-sized EMS provider increased throughput by 22% without sacrificing accuracy by adopting a hybrid setup. They used a 16,000 CPH machine for standard components and a dedicated 8,000 CPH system for fine-pitch ICs. Supported by real-time error correction algorithms, this configuration reduced bottlenecks and maintained 99.92% placement accuracy across mixed-volume production runs.

Precision, Accuracy, and Yield Impact in Component Placement

Tolerances and Placement Accuracy: µm-Level Performance

Today's surface mount technology machines can place components with around 15 micrometer accuracy, which makes them suitable for those tiny 0201 parts and micro BGA packages that used to be real headaches. The reason they pull off such fine work? High res cameras paired with servos that move just right every time. Most factories report defect rates under 0.01% when everything runs smoothly, though that number climbs a bit when there are temperature fluctuations or other production hiccups. Some of the top end equipment on the market these days comes with smart vision systems powered by artificial intelligence. These systems actually adjust themselves on the fly for things like heat expansion or warped circuit boards during component placement, something that would have required manual calibration not too long ago.

Impact of Mechanical Stability and Calibration on Consistency

Vibration-dampened frames and temperature-compensated linear guides ensure consistent performance over extended production cycles. Proper calibration reduces positional drift by 73% over 500 operating hours, directly contributing to a 1.8% improvement in yield for multilayer PCB assemblies.

How Reduced Human Error Improves Yield Rates

Automation eliminates manual handling errors responsible for 37% of placement defects. Closed-loop feedback systems verify component orientation before placement, reducing misaligned ICs by 92% compared to semi-automated processes.

Industry Paradox: High Speed vs. Ultra-Fine Pitch Component Accuracy

While 50,000 CPH machines dominate mass production, their accuracy often drops to ±35µm–insufficient for 0.3mm pitch components. New hybrid systems overcome this limitation by maintaining ±20µm precision at 40,000 CPH through predictive motion control, addressing critical needs in medical and aerospace applications.

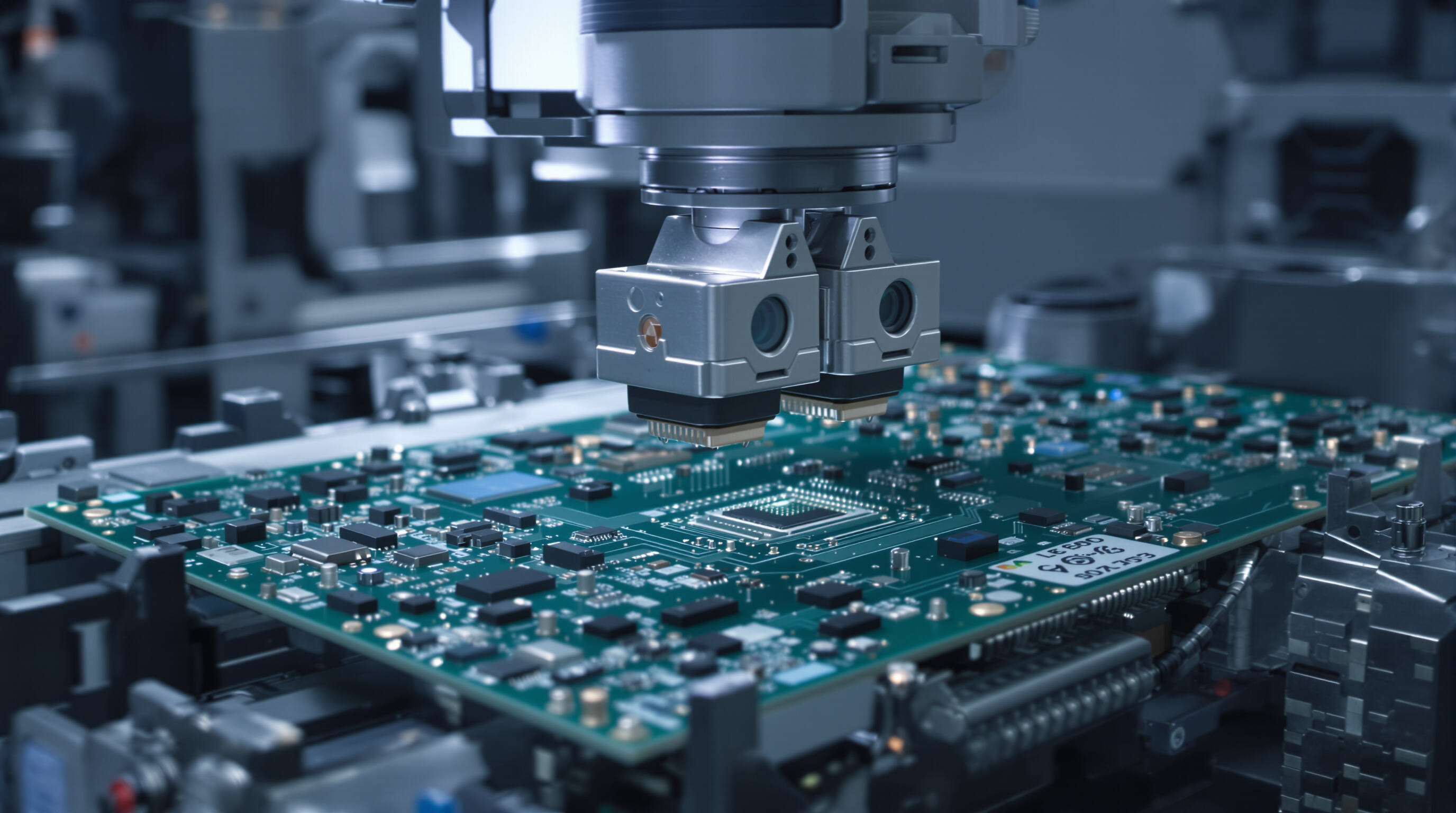

Vision Systems for Real-Time Alignment and Error Detection

Modern SMT pick and place machines rely on advanced vision systems to achieve micron-level accuracy in high-speed PCB assembly. These systems combine optical sensors, high-resolution cameras, and machine-learning algorithms to verify component positioning 50–100 times faster than human operators.

Role of vision systems in automated component placement using SMDs

Vision-guided systems use dual-side recognition to map PCB fiducial markers and component orientations, correcting offsets caused by material warping or feeder inconsistencies. This automated verification reduces manual inspection needs by 75% in high-mix environments, as outlined in IPC-9850B standards.

Types of vision systems: overhead, line-scan, and fiducial detection

- Overhead systems (12–25MP cameras) capture global PCB alignment

- Line-scan cameras track component pick accuracy at conveyor speeds up to 3.6 m/sec

- Multi-spectral fiducial recognition compensates for board flexure and thermal expansion

Real-time error correction and misalignment prevention

Closed-loop feedback compares actual placement positions with CAD data in under 2ms, automatically adjusting nozzle rotation and placement force. This rapid correction prevents tombstoning in 0201 components and BGA skew errors during high-speed operation.

Innovative features in modern vision-guided SMT machines

Leading manufacturers now incorporate:

- 10µm alignment accuracy via hybrid laser/optical measurement

- Self-calibrating thermal compensation for ±0.5°C environmental fluctuations

- AI-driven defect pattern recognition that improves yield rates by 0.4% monthly

These capabilities support first-pass yields above 99.2% in complex automotive PCBs while sustaining 45,000 CPH throughput.

Component Handling Flexibility: Size, Shape, and Feeder Integration

Today's surface mount technology pick and place machines need to work with all sorts of components, from those teeny tiny 01005 resistors measuring just 0.4 by 0.2 millimeters right up to big integrated circuit packages that can be as large as 50 mm square. The 2024 Component Miniaturization Report actually highlights this wide range requirement for modern manufacturing equipment. And it makes sense when we look at what industries are demanding these days. Medical Internet of Things devices and automotive electronics applications often require boards that mix miniature sensors with much larger connectors all in one design space. Manufacturers have had to adapt their machinery to handle this combination without compromising quality or production speed.

Nozzle Types and Their Importance in Handling Diverse Components

Vacuum nozzles are tailored to component geometry:

- Capillary nozzles for 01005 chips

- Multi-stage nozzles for mixed-size placements

-

Custom grippers for odd-form components like electrolytic capacitors

Quick-swap nozzle racks reduce changeover time by up to 73% compared to single-nozzle systems, according to IPC-9850 standards.

Flexibility in Managing Odd-Form and Through-Hole Components

While optimized for SMDs, advanced machines can also place press-fit connectors, shielding cans, and through-hole jumpers using optional placement arms. Automated vision compensation adjusts for component warpage up to 0.3mm–common in lead frames–ensuring reliable placement.

Types of Feeders: Tape, Stick, Matrix Tray, and Bulk

| Feeder Type | Component Compatibility | Speed (CPH) | Reload Frequency |

|---|---|---|---|

| Tape-on-Reel | 01005 to 24mm ICs | 8,000–12,000 | Every 4–8 hrs |

| Stick Feeder | LEDs, Connectors | 1,200–2,500 | Manual reload |

| Matrix Tray | QFNs, BGAs | 300–500 | 1–2x per shift |

| Bulk Vibratory | Resistors, Capacitors | 20,000+ | Continuous |

Automated Feeder Indexing and Quick-Change Systems

Tape feeders with auto-indexing reduce setup errors by 92% compared to manual models, based on iNEMI 2023 findings. Magnetically-locked feeder bases enable full line reconfiguration in under 15 minutes–essential for high-mix, low-volume production.

Maximizing Uptime With Smart Feeder Monitoring

Integrated sensors monitor tape jam risk through vibration analysis, provide low-component alerts (<10% remaining), and detect feeder alignment drift beyond ±25µm. This predictive approach cuts unplanned downtime by 40%, according to the 2023 Smart Manufacturing Benchmark.

Future-Proofing Your SMT Pick and Place Machine Investment

Scalability and Software Upgradability in Modern SMT Machines

Modern SMT equipment features modular architectures enabling up to 35% capacity expansion through add-on modules. Leading vendors offer backward-compatible software updates that support new component libraries and communication protocols such as IPC-CFX, ensuring long-term relevance.

Integration With Industry 4.0 and Smart Factory Ecosystems

IoT-enabled machines have helped tier-1 EMS providers boost first-pass yields by 18%, according to the 2024 Smart Manufacturing Report. Equipped with dual-LAN ports and OPC-UA compatibility, these systems enable seamless real-time integration with MES and ERP platforms.

Evaluating Modular Design Capabilities

Top-tier machines now feature tool-free reconfigurable gantries and swappable nozzle racks. Field-upgradable vision systems–from 2MP to 12MP camera modules–ensure readiness for emerging component technologies like 0201 metric passives.

Long-Term ROI: Balancing Cost and Technological Longevity

Mid-range machines paired with 7-year service contracts demonstrate 22% lower total cost of ownership compared to premium models reliant on specialized technicians, making them a strategic choice for sustainable operations.

User Interface, Programming Ease, and Changeover Speed

| Feature | Time Savings |

|---|---|

| Drag-and-drop feeder mapping | 43% faster setup |

| AI-assisted component recognition | 67% faster program creation |

Data Analytics and Predictive Maintenance Capabilities

Embedded vibration sensors and thermal imaging detect early signs of bearing or actuator wear, reducing unplanned downtime by 31% through proactive maintenance alerts.

Energy Efficiency and Footprint Optimization

New linear motor designs consume 19% less energy while maintaining 0.025mm placement accuracy. Compact models occupying just 1.8m² now support 85% of standard panel sizes, optimizing floor space in dense production environments.

FAQ

What is CPH in SMT machines?

CPH stands for Components Per Hour, indicating how many components a machine theoretically places in perfect conditions within an hour.

Why is cycle time important for SMT machines?

Cycle time measures the actual pace at which a machine moves from one placement to the next, affecting real-world productivity beyond theoretical CPH.

How does automation reduce human error in SMT processes?

Automation minimizes manual handling errors by ensuring precise component placements, significantly improving yield rates.

What's the trade-off between high-speed placement and precision in SMT?

Increasing placement speed often reduces accuracy due to mechanical vibrations; however, enhanced stabilization technologies can mitigate this trade-off.

What role do vision systems play in SMT machines?

Vision systems ensure micron-level accuracy in component placements through advanced sensors and AI algorithms, reducing manual inspection.

Table of Contents

- Speed, Throughput, and Production Volume Alignment About SMT Pick and Place Machine

- Precision, Accuracy, and Yield Impact in Component Placement

- Vision Systems for Real-Time Alignment and Error Detection

- Component Handling Flexibility: Size, Shape, and Feeder Integration

- Future-Proofing Your SMT Pick and Place Machine Investment

- Scalability and Software Upgradability in Modern SMT Machines

- Integration With Industry 4.0 and Smart Factory Ecosystems

- Evaluating Modular Design Capabilities

- Long-Term ROI: Balancing Cost and Technological Longevity

- User Interface, Programming Ease, and Changeover Speed

- Data Analytics and Predictive Maintenance Capabilities

- Energy Efficiency and Footprint Optimization

- FAQ