Precision Engineering: The Role of Accuracy in High-End SMT Pick and Place Machines

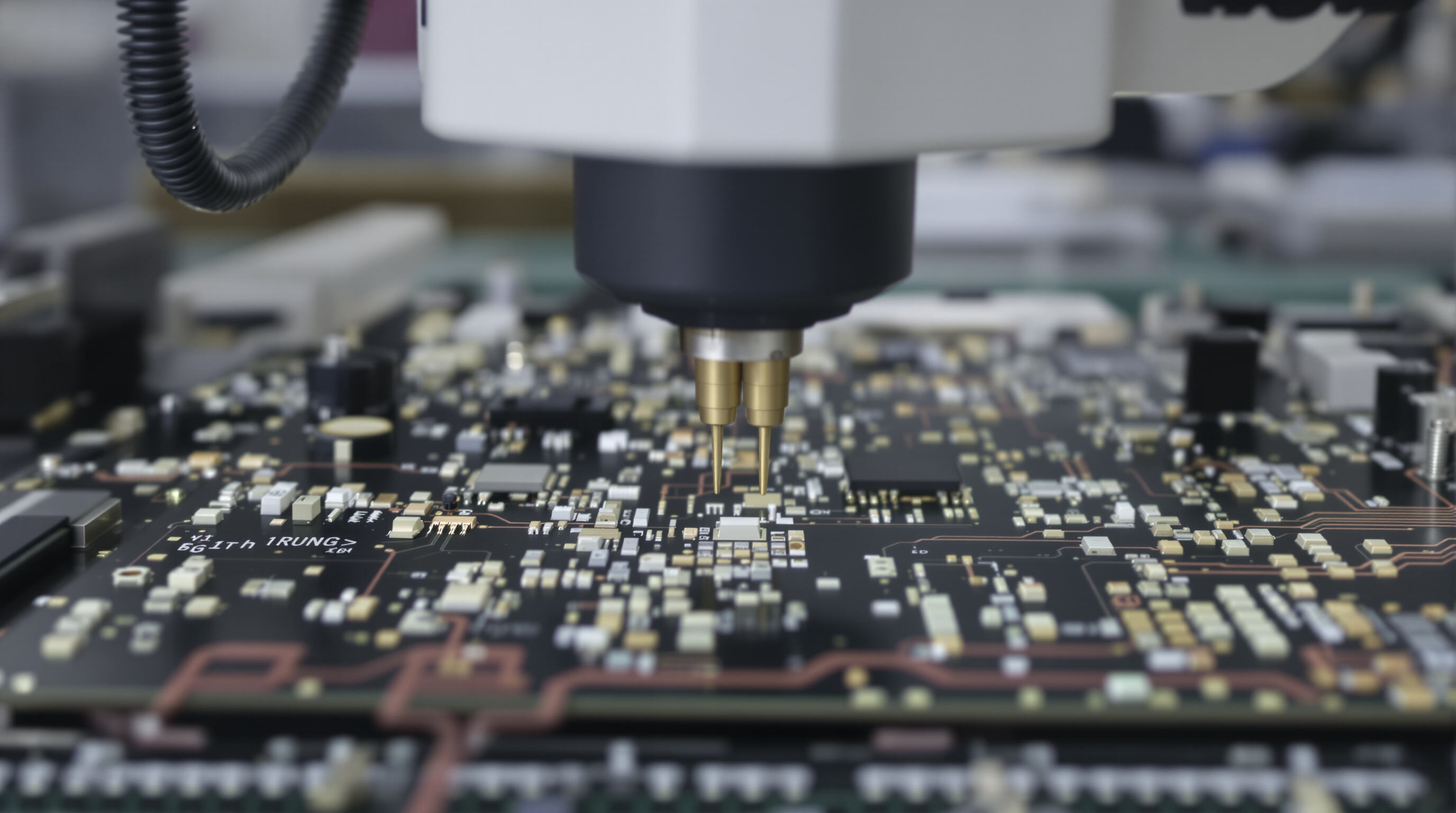

Understanding Placement Accuracy and Its Impact on PCB Assembly Quality

Getting the placement right on SMT pick and place machines means components land within about 0.025 to 0.05 millimeters from where they should be, which makes all the difference for first pass yields. A recent look at IPC-9850 standards from 2023 showed something interesting – machines that hit around 30 microns or better cut down soldering problems by nearly two thirds when compared to equipment working with 50 micron tolerances. When dealing with these tiny parts like 01005 passive components measuring just 0.4 by 0.2 mm or those micro BGA packages spaced at 0.3 mm between balls, even the slightest error matters. Components placed incorrectly will either leave gaps in the circuit or cause those annoying tombstone effects we all know too well in production lines.

Vision Systems and Fiducial Recognition for Micron-Level Component Alignment

Modern vision systems now incorporate multi-spectral imaging capabilities that can pick up tiny details down to around 5 microns in size. These systems are smart enough to compensate for common issues like PCB warping (which typically ranges between plus or minus 0.15mm per square meter) and thermal expansion effects (about 5 microns per degree Celsius for standard FR4 materials). The closed loop fiducial tracking technology keeps component placement within tight tolerances of approximately 10 microns across entire circuit boards. This level of accuracy holds true even when dealing with solder paste deposits as thin as 0.1mm. With their 25 megapixel global shutter cameras and image processing speeds below 3 milliseconds, today's advanced systems handle production rates reaching up to 50,000 components per hour while still maintaining precise alignment throughout manufacturing runs.

Mechanical Stability, Calibration, and Long-Term Precision Maintenance

The granite base material has a really low thermal expansion rate around 6×10⁻⁶ per degree Celsius, making it ideal for precision work. When paired with linear motors that can repeat positions within less than half a micrometer, these components create rock solid mechanical stability for the system. Keeping things accurate requires regular checks against NIST traceable standards since nozzles tend to wear down over time and affect performance. Industry reports from 2024 show interesting results: machines calibrated every day stay within plus or minus 8 micrometers after running for 10 thousand hours. That's way better than what happens when systems only get checked once a week where drift typically reaches around ±25 micrometers. The difference makes a big impact on long term accuracy and reliability.

Is Sub-20-Micron Accuracy Necessary for All High-End SMT Applications?

Getting down to sub-20 micrometer accuracy matters a lot in industries where failure isn't an option, like aerospace engineering and medical device manufacturing. But for regular consumer gadgets, going this fine just doesn't pay off much. According to the JEDEC standard from 2022 (JESD94B), most everyday products don't see any real quality boost past around 35 micrometers. And let's talk money too machines that can hit those super tight tolerances cost about 27 percent more to maintain over time. So why bother? Well, these precision tools really shine when working on tiny components with lead spacing under 0.15 millimeters or dealing with ball grid arrays that have more than 1,200 input/output points. That's where the extra investment actually makes sense.

Speed and Throughput: Balancing Efficiency in SMT Pick and Place Machine Performance

Components per hour (CPH) as a benchmark for real-world production efficiency

High-end SMT pick and place machines achieve throughput rates from 20,000 to over 100,000 CPH, though actual performance depends on board complexity. As IPC-9850 testing shows, assemblies incorporating fine-pitch components like 0201 passives or 0.4mm-pitch BGAs typically operate at 12–18% below peak CPH due to slower placement cycles and tighter accuracy requirements.

Feeder technologies and their role in minimizing pick-and-place cycle time

Tape feeders that can retrieve components in under 8 milliseconds offer roughly 35% quicker part pickup compared to older systems. The newer dual lane, high density models slash material switching time by about half. Servo driven versions are especially smart since they automatically tweak tape tension during operation, which helps avoid those frustrating alignment problems that slow down production lines. All these upgrades mean machines spend less time sitting idle. Factory floor reports from top manufacturers show feeder related downtime has dropped below 0.5% according to recent 2023 data collected across multiple manufacturing sites.

Trade-offs between speed and placement accuracy in high-volume manufacturing

When machines operate above 85% of their maximum cycles per hour (CPH) capacity, placement deviations tend to jump between 15 and 30 micrometers, which really hurts yields in those precision sensitive assembly jobs. Applications that need around plus or minus 25 micrometer accuracy work best when running at about 65 to 75% of top throughput. This sweet spot balances speed with quality requirements. Modern equipment now comes with adaptive motion controls and thermal stabilization features that actually make a difference here. These systems cut down on speed related errors by roughly 40%, all while keeping most of what theory says should be possible in terms of throughput rates, somewhere around 90% in practice.

Intelligent Automation: AI and Machine Learning in SMT Pick and Place Systems

AI-Powered Optimization for Adaptive Placement and Process Refinement

Modern AI systems look at all sorts of live data during PCB assembly work including things like board layouts, available components, and even environmental factors to figure out the best way to place parts. The smart systems then pick the right nozzles for different jobs and focus extra attention on areas where components are packed closely together, which helps cut down on how long each assembly takes. According to research published last year from the Electronics Manufacturing Research Consortium, factories using these AI guided processes saw about a 40% drop in mistakes when placing components compared to older fixed programming approaches. That kind of improvement makes a real difference in production quality and efficiency.

Real-Time Error Correction and Self-Diagnosis Using Embedded Intelligence

Machine learning systems built into production lines can spot defects right away, like when parts aren't lined up properly or there's solder bridging between connections. These smart sensors work by checking what's happening now against past records, so they catch problems before things get worse. The latest numbers from industry automation reports show something interesting too. When issues get fixed as soon as they appear, companies save around 30% on fixing mistakes in complex manufacturing setups. Beyond just finding faults, these systems run their own checks regularly. They keep an eye on things like vacuum pressure levels and how motors are performing, giving workers warnings about subtle changes that might indicate equipment is starting to drift out of spec over time.

Predictive Maintenance and Reduced Downtime Through Smart Monitoring

Modern machine learning systems look at how equipment vibrates and track successful operations to predict when bearings will wear out, feeders might fail, or nozzles start degrading. These predictions actually help extend the average time between breakdowns by around 25 to 30 percent over traditional scheduled maintenance approaches. When machines are connected to monitoring systems, they show interesting links between air moisture levels and how well actuators work, which lets operators make adjustments based on actual weather conditions rather than guesswork. Many leading companies in manufacturing have managed to keep unexpected stoppages down to less than 1% of total operations time these days, something that was almost unheard of just a few years ago.

Industry 4.0 Integration: Smart Connectivity in Modern SMT Pick and Place Machines

IoT and Cloud Connectivity for Real-Time Monitoring and Remote Control

SMT machines equipped with IoT technology send encrypted operation details to cloud platforms across the enterprise. These include things like placement accuracy under 15 microns, machine uptime above 98 percent, and current inventory status. Connecting these systems to ERP software cuts down on unexpected downtime by around 30% according to recent industry reports from 2024. The secure remote access feature means techs can tweak vision systems settings or make adjustments to feeders through a virtual private network. This saves time when there's an urgent problem because nobody has to physically travel to the site anymore. Some companies report response times cut in half since implementing this kind of setup.

Data-Driven Decision Making with Analytics from Connected SMT Equipment

Edge computing takes all that messy machine data and turns it into something useful for factory managers. According to various industry reports, factories that implement these analytics solutions see their production cycles speed up by around 22%. The real magic happens when machine learning starts spotting patterns nobody else would notice. For instance, some systems detect when parts start getting misaligned after about 50 thousand placements, which lets maintenance teams fix problems before they become big headaches. On production lines where lots of different products are made, these smart systems actually rearrange the order of jobs depending on what's going wrong right now and what parts are actually available. This kind of thinking saves money because nobody wants to waste good materials on defective products.

Interoperability Standards (IPC-HERMES, SMEMA) Enabling Seamless Factory Integration

Adoption of IPC-HERMES-9852 and SMEMA protocols enables direct communication between pick and place machines, stencil printers, reflow ovens, and AGVs without middleware. Production lines using these standards achieve 40% faster changeovers through synchronized equipment commands via unified APIs, ensuring seamless interoperability across more than 15 equipment brands.

FAQ

What is the importance of precision in SMT pick and place machines?

Precision in SMT pick and place machines ensures accurate placement of components, which is crucial for achieving high first pass yields and reducing errors such as soldering defects.

How do vision systems contribute to SMT accuracy?

Vision systems use advanced imaging technology to align components with precision, compensating for common issues like PCB warping and thermal expansion, thus ensuring optimal placement accuracy.

Is maintaining sub-20-micron accuracy necessary for all applications?

No, sub-20-micron accuracy is vital for industries where precision is critical, such as aerospace and medical devices, but for consumer electronics, a 35-micron accuracy is often sufficient.

How do AI and machine learning enhance SMT pick and place systems?

AI and machine learning optimize placement processes, reduce errors, and enable real-time error correction, leading to improved production quality and reduced downtime.

What role does IoT play in modern SMT machines?

IoT technologies enable real-time monitoring, cloud connectivity, and remote control, which enhance efficiency, reduce downtime, and allow for swift problem resolution.

Table of Contents

- Precision Engineering: The Role of Accuracy in High-End SMT Pick and Place Machines

- Speed and Throughput: Balancing Efficiency in SMT Pick and Place Machine Performance

- Intelligent Automation: AI and Machine Learning in SMT Pick and Place Systems

- Industry 4.0 Integration: Smart Connectivity in Modern SMT Pick and Place Machines

-

FAQ

- What is the importance of precision in SMT pick and place machines?

- How do vision systems contribute to SMT accuracy?

- Is maintaining sub-20-micron accuracy necessary for all applications?

- How do AI and machine learning enhance SMT pick and place systems?

- What role does IoT play in modern SMT machines?