The Importance of SMT Production in Automotive Electronics

How SMT Technology Supports Modern Automotive Electronics

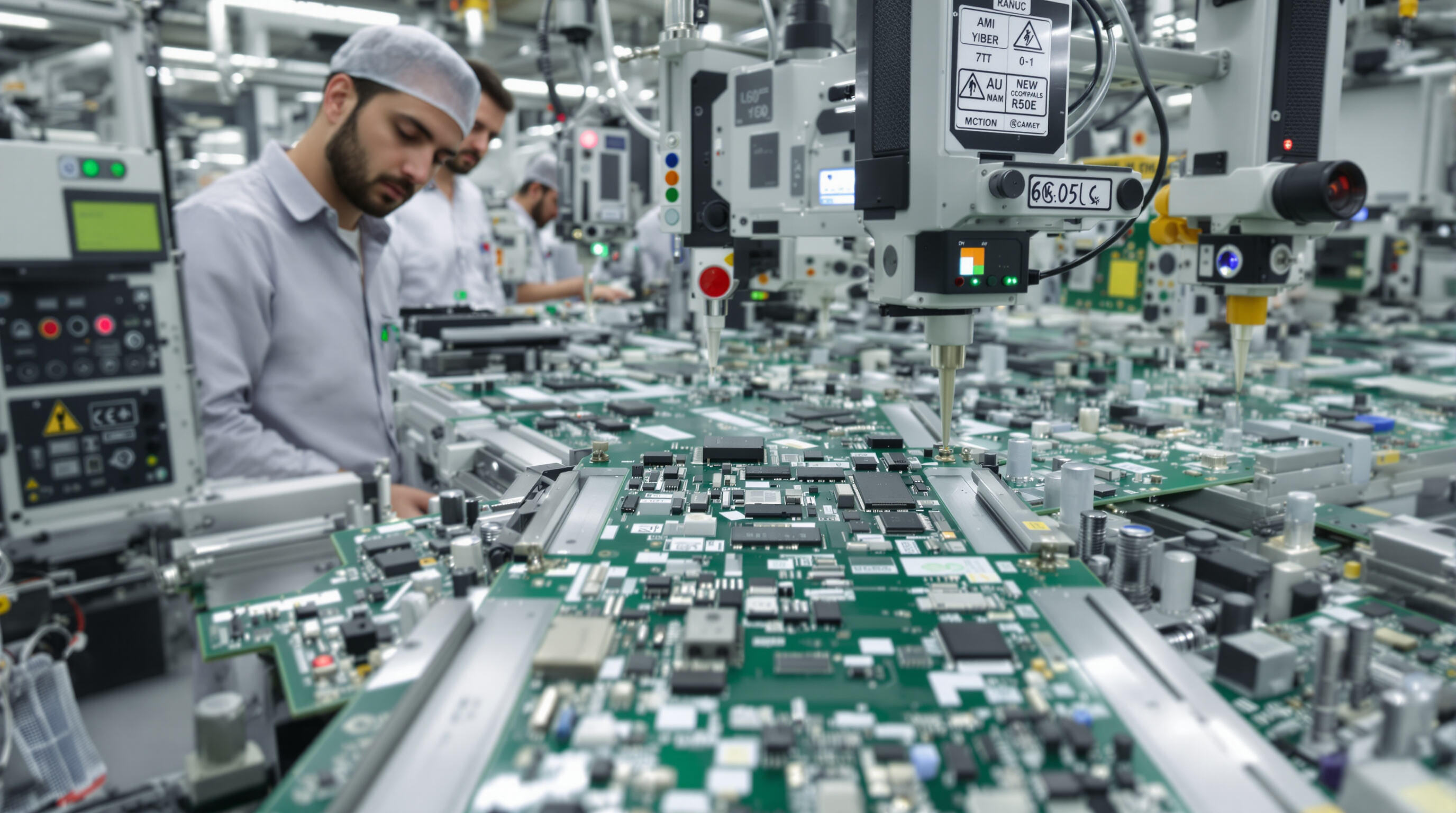

Surface Mount Tech, or SMT for short, makes it possible to shrink down parts and boost reliability in modern car tech like those fancy ADAS systems, infotainment gadgets, and all sorts of electronic control units inside vehicles. When components get mounted right on top of the PCB instead of through holes, this approach cuts down both weight and space requirements. Plus, signals travel better too, which matters a lot for electric cars and self-driving tech where every bit counts. Some research from last year looked into how auto makers are adapting to electric powertrains, and they discovered something interesting: around four out of five EV producers have started leaning heavily on SMT when designing dense circuit boards. These manufacturers need their electronics to perform well even when things get hot under the hood or exposed to road salt and other nasty stuff.

Key Challenges in SMT Quality for Automotive Applications

The automotive SMT manufacturing process needs to stand up to pretty tough conditions. Components often face temperature extremes ranging from -40 degrees Celsius all the way up to 150 degrees, plus constant vibrations throughout their lifespan. Things get even trickier when parts become smaller like those tiny 01005 packages measuring just 0.4mm by 0.2mm. At these sizes, getting solder joints right becomes almost impossible without microscopic level accuracy. The good news is that Industry 4.0 tech has made a real difference lately. Top manufacturers report around a two-thirds drop in placement mistakes since 2022 thanks to better automation systems. Still, there are ongoing issues with managing heat properly across different materials and creating solder connections free from air pockets remains a persistent challenge for many plants.

Regulatory Standards (IATF 16949) and Their Impact on SMT Manufacturing

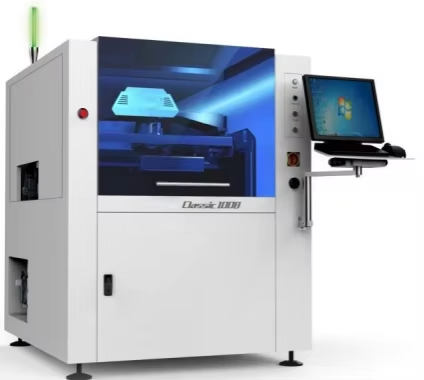

IATF 16949 sets pretty tight controls on automotive surface mount technology lines these days. Every printed circuit board batch needs to be fully traceable from start to finish. If defects creep above that 0.1% threshold, production just stops cold, which explains why so many plants now run those real time SPC dashboards all over the shop floor. Suppliers aiming for that elusive zero defect target spend hours checking things like solder paste consistency and making sure stencils stay clean throughout shifts. Some companies have even started tracking temperature fluctuations in their paste printers as part of their quality checks.

Enhancing Reliability Through SMT Process Optimization

The best surface mount technology lines today combine automated optical inspection with machine learning algorithms that predict defects before they happen. Manufacturers reported hitting first pass yields around 99.95% back in 2023 across the industry. Some companies have made real progress too - nitrogen reflow soldering cuts down on oxidation issues by roughly 40%. And when it comes to applying solder paste accurately during those massive production runs, 3D SPI systems maintain about plus or minus 5% accuracy most of the time. All these upgrades are starting to pay off in practical ways. Warranty claims for electronic control units dropped by nearly 30% over five years as factories implemented these better practices.

End-to-End Component Traceability in SMT Processes

Modern automotive electronics demand flawless surface-mount technology (SMT) production, where end-to-end traceability ensures compliance with quality standards and accelerates defect resolution. Tracking components from origin through final assembly helps prevent counterfeit parts and process deviations that could compromise vehicle safety.

Traceability from Supplier to Final Assembly on the PCB

Tracking every detail matters a lot in automotive SMT workflows, starting right from checking supplier certifications all the way through to keeping track of specific material batch numbers. Every single component gets its own special ID tag these days, whether it's a resistor, capacitor or integrated circuit. These identifiers help confirm genuine parts and stop components getting lost or mixed up when building PCBs. The extra attention paid off because problems with wrong solder alloys or old reel materials cause around 23 percent of defects in automotive SMT processes according to recent industry data. That kind of oversight makes all the difference in quality control for manufacturers dealing with complex electronics assemblies.

Micro-Traceability via Data Logging and Real-Time Process Monitoring

Modern pick and place machines along with reflow ovens come loaded with all sorts of sensors that gather really fine detail information about things like how much solder paste is applied, where components land on the board (usually within about 15 microns), and complete thermal maps throughout the process. When something goes wrong, these systems actually send out warnings right away so problems can be fixed before they become bigger issues. Take temperature changes in a reflow oven for example anything over roughly 2 degrees Celsius will set off an automatic correction mechanism. This helps maintain solid connections in those critical engine control units located beneath vehicle hoods where reliability is absolutely essential.

Role of Manufacturing Execution Systems (MES) in Enabling Traceability

MES systems serve as the main point for tracking everything throughout production, bringing together data from machines, parts history, and quality checks all on one screen. Take the case of finding a bad airbag sensor module. With MES, manufacturers can actually track exactly which batch of solder paste was used, where the feeder was positioned, and even pinpoint the specific oven section that processed it. This cuts down the time needed to figure out what went wrong by about 40%, something that would take days if done manually. For plant managers dealing with recalls or quality issues, this kind of visibility makes troubleshooting much less painful.

Ensuring Process Consistency Through Traceable SMT Workflows

Standardized workflows with embedded traceability minimize variability across high-volume SMT operations. Automated alerts notify engineers if a component exceeds its moisture sensitivity storage limit or if stencil wear affects solder deposition. This closed-loop control ensures consistent, automotive-grade reliability even during continuous 24/7 production.

Advanced Quality Assurance in Automotive SMT Manufacturing

Modern automotive electronics demand near-zero defect rates, driving SMT production to adopt automated quality assurance systems that combine precision inspection with data-driven process control. Over 92% of automotive PCB manufacturers now deploy multi-stage inspection protocols to meet stringent AEC-Q100 reliability standards (2024 Automotive Electronics Council Report).

Automated Optical Inspection (AOI) and X-Ray Inspection for Defect Detection

AOI systems use high-resolution cameras to scan solder joints and component placements at 15µm resolution, detecting defects like tombstoning or bridging in milliseconds. For hidden connections beneath BGAs or QFNs, X-ray inspection achieves 99.7% detection accuracy by identifying solder ball voids as small as 5% of joint volume.

Component-Level Inspection in High-Density SMT Assemblies

With 0201 metric components (0.2mm × 0.1mm) increasingly common, automated pick-and-place systems employ laser profilometry to verify part orientation before soldering. After reflow, cross-sectional imaging validates solder fillet geometry against IPC-610 Class 3 requirements - critical for modules subjected to constant vibration.

Error Detection, Root Cause Analysis, and Debugging in SMT Lines

Real-time SPC dashboards correlate minor deviations - such as stencil printing pressure changes (±0.02kgf/cm²) - with variations in solder paste volume, triggering preventive alarms. When defects occur, traceable process data from MES platforms isolates root causes 63% faster than manual log reviews.

Data-Driven Continuous Improvement for Reliable SMT Output

Leveraging Process Data for Predictive Quality Control

Today's surface mount technology lines rely on real time monitoring systems that catch potential quality problems long before they become actual issues. When looking at things like how much solder paste gets applied (with a tolerance range of plus or minus 3%) and where components land on the board (accuracy within 0.025mm), most factories implement what's called Statistical Process Control or SPC for short. This helps them hit those Six Sigma standards everyone talks about these days. According to some recent research from the automotive manufacturing sector back in 2023, when plants install these closed loop feedback mechanisms, they actually cut down defects in brake control module production by around 40%. The secret? Making small but smart adjustments to process parameters right in the middle of solder reflow operations.

Continuous Improvement Through SMT Production Analytics

Advanced analytics platforms track more than 15 quality metrics simultaneously, including:

- First Pass Yield (FPY) improvements from 88% to 94%

- Mean Time Between Defects (MTBD) increases of 22%

- Thermal cycling test pass rates exceeding IATF 16949 requirements

These insights enable root cause analysis in under 25 minutes, significantly faster than traditional 4-hour manual inspections.

Balancing Speed and Precision in High-Volume Automotive SMT Runs

Automotive electronics manufacturers achieve 98.6% line efficiency through:

| Parameter | Standard Value | Automotive Requirement |

|---|---|---|

| Placement CPK | ≥1.33 | ≥1.67 |

| Reflow Profile Adherence | ±5°C | ±2°C |

| AOI False Call Rate | <2% | <0.8% |

AI-driven vision systems sustain placement speeds of 47,500 components/hour while detecting 0.4mm solder bridges in ADAS camera modules. This balance of speed and precision reduces warranty claims by 31% compared to conventional methods.

FAQ

What is Surface Mount Technology (SMT) in automotive electronics?

Surface Mount Technology (SMT) is a method for producing electronic circuits where the components are mounted directly onto the surface of printed circuit boards (PCBs). It is widely used in automotive electronics to create compact, reliable, and efficient components.

Why is traceability important in SMT production?

Traceability is crucial in SMT production to ensure quality control, prevent counterfeit components, and address process deviations. It helps in tracking components from supplier to final assembly, facilitating quick resolution of issues and compliance with standards like IATF 16949.

What challenges are associated with SMT in automotive applications?

Challenges in automotive SMT include managing extreme temperature conditions, maintaining solder joint precision on small packages, and dealing with vibrations. There's also the need for meticulous heat management and preventing air pockets in solder connections.

How has automation improved SMT production quality?

Automation in SMT production, through Industry 4.0 technologies, has significantly reduced placement errors, improved defect prediction, and enhanced process control. Systems like Automated Optical Inspection (AOI) and machine learning algorithms play a key role in maintaining high-quality standards.