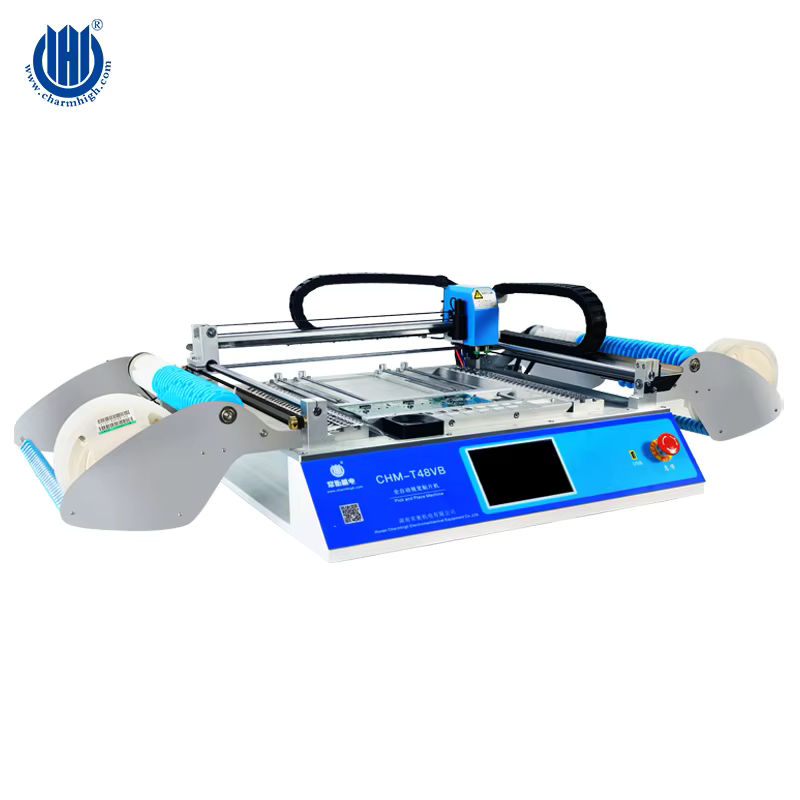

New Smt Equipment Desktop Vision Pick and Place CHM-T48VB with 2 Mounting Heads

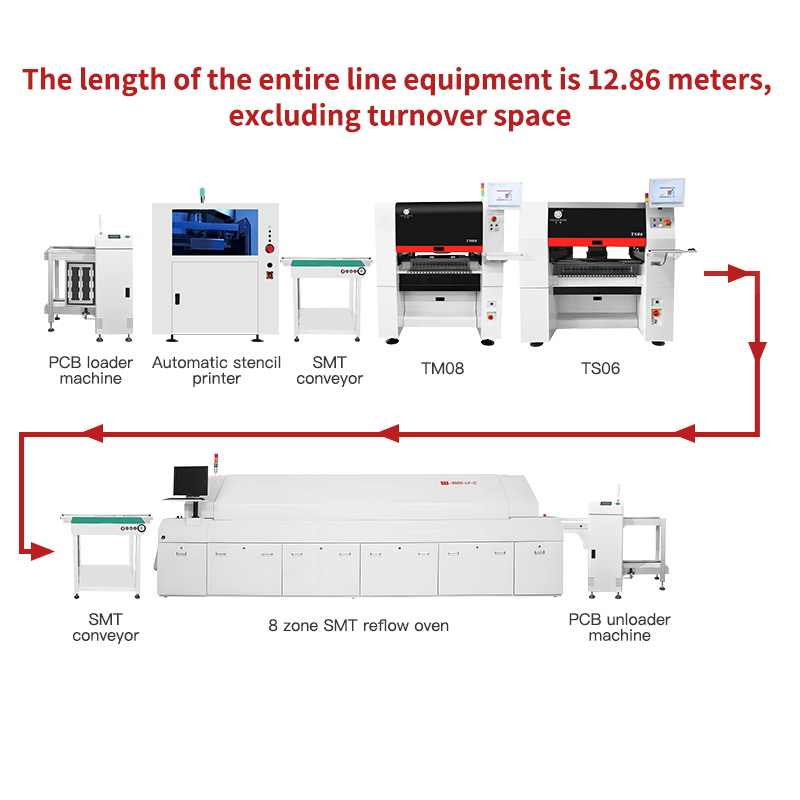

High-efficiency CHM LS08 visual mounter with 8 heads, ideal for LED DOB and PCB assembly. Offers fast mounting speed, stable performance, and accurate vision alignment for modern SMT production lines.

- Overview

- Parameter

- Recommended Products

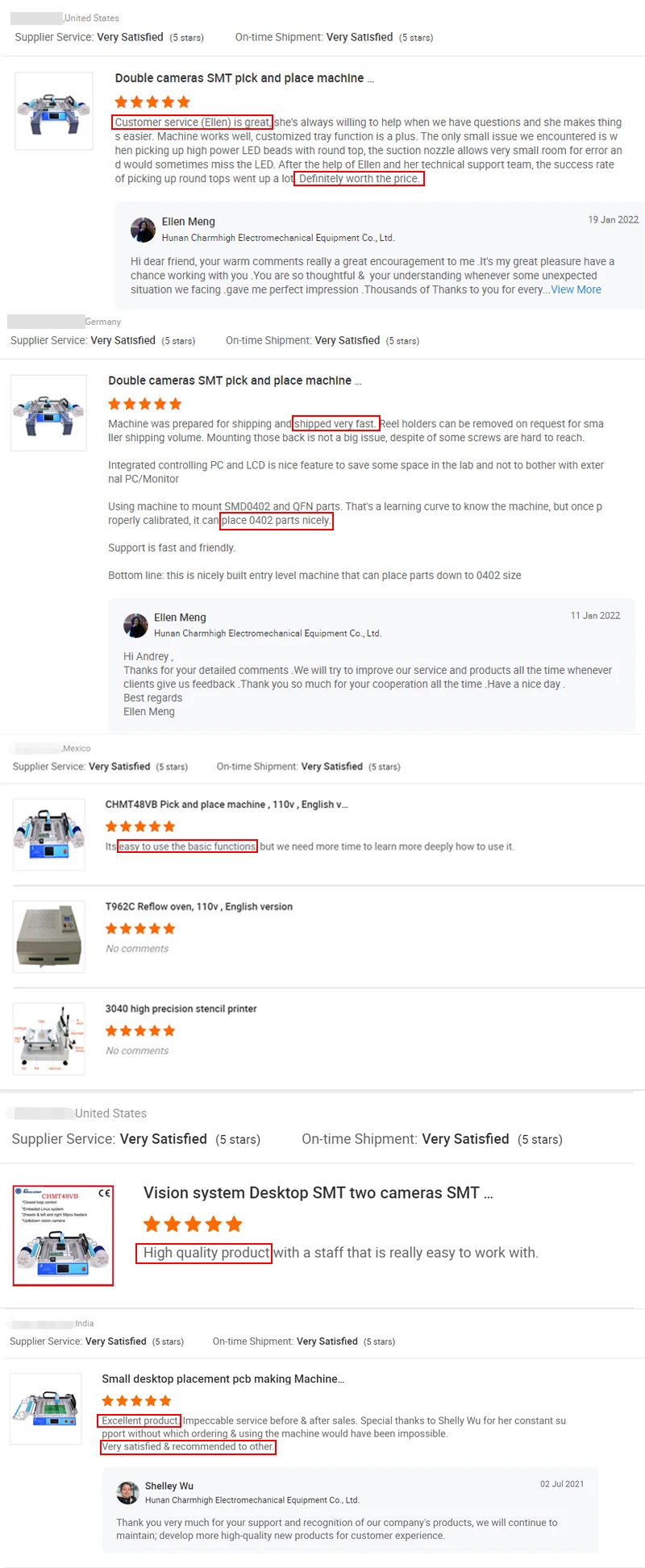

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment.

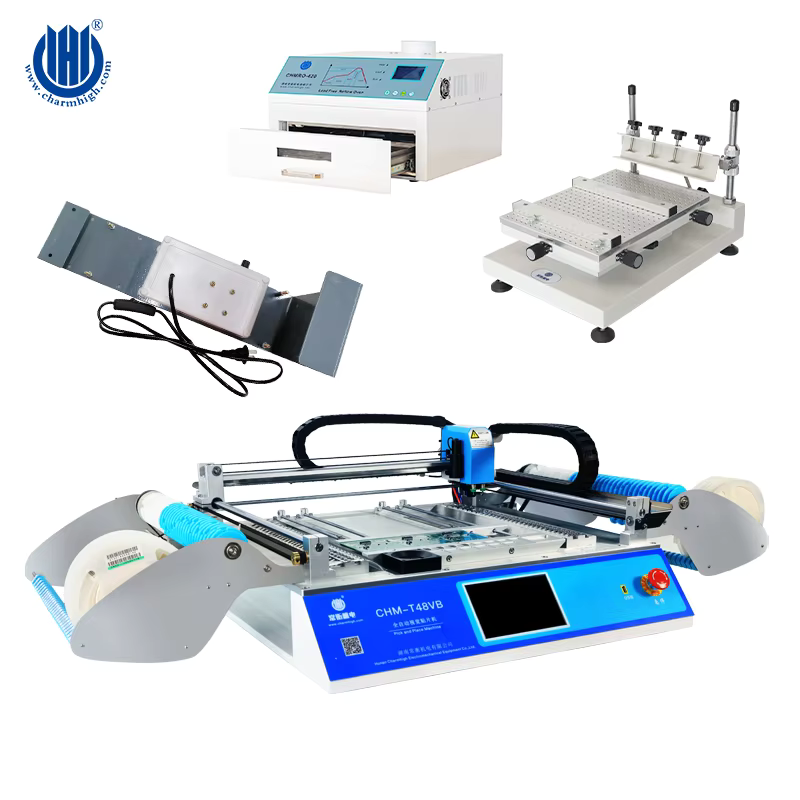

3.What can you buy from us?

Pick and place machine, smt production line, stencil printer, reflow oven, cnc machine

4. Why should you buy from us not from other suppliers?

Hunan Charmhigh Electromechanical Equipment Co., Ltd. has been a modern science and technology enterprise fully capable of research&development, manufacturing, and marketing of pick and place machine as well as SMT peripheral equipment for over 12 years.

5. What services can we provide?

Accepted Delivery Terms: FOB, EXW; Accepted Payment Currency: USD, CNY;

Accepted Payment Type: T/T,Credit Card,Cash; Language Spoken: English, Chinese.

Specification

|

Dimensions

|

1310mm(L)×710mm(W)×340mm(H)

|

|

Weight

|

49kg

|

|

Power Supply

|

AC220V (50Hz, single phase) /AC110V (60Hz, single phase);

300W |

|

Air Supply

|

No external air supply required

|

|

Vacuum Generation

|

Built-in vacuum pump

|

|

Mounting Head Quantity

|

2

|

|

Mounting Speed

|

6000cph (optimal without vision detection);

4000cph (optimal with vision detection) |

|

Control Accuracy

|

0.025mm

|

|

Component Type

|

0402/0603~5050/SOT/SOP/QFP/QFN/BGA, etc.

(resistor/capacitor/diode/triode/LED/IC, etc.) |

|

PCB Thickness

|

0.6mm~3.5mm

|

|

PCB Size

|

10mm(L)×10mm(W)~345mm(L)×360mm(W)

|

|

PCB Conveying

|

Manual operation

|

|

Nozzle Change

|

Manual operation

|

|

Control System

|

Built-in computer(embedded Linux operating system),

7-inch touch screen |

|

|

X&Y-axisdriven by stepping motors in the way of closed-loop control realized by encoder; Z-axis capable of reset detection;all

motors adopting flexible S-curve acceleration and deceleration; tape puller automatic reset supported |

|

Transmission System

|

Synchronous belt + polished rod +linear guide

|

|

|

58 tape feeding stacks(8mm:44,12mm:8;16mm:4,24mm:2;customization supported), 14 preset general IC stacks, worksurface custom IC

trays and stick feeder supported |

|

|

Up-looking camera for component automatic calibration (component size applicable: 22mm×22mm); down-looking camera for PCB

calibration via Mark Point and component positioning |