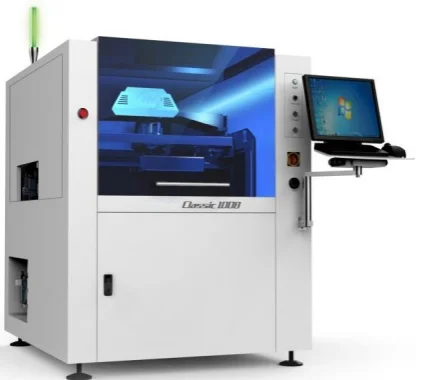

Charmhigh PC6635 Fully Computer Controlled Lead-free Reflow Oven Cost Effective Lead Free With Custom Made Track

CHM LS08 visual mounter features 8 high-speed heads for efficient LED DOB and PCB assembly. Offers accurate component placement, stable performance, and a streamlined SMT production line for professional manufacturing.

- Overview

- Parameter

- Recommended Products

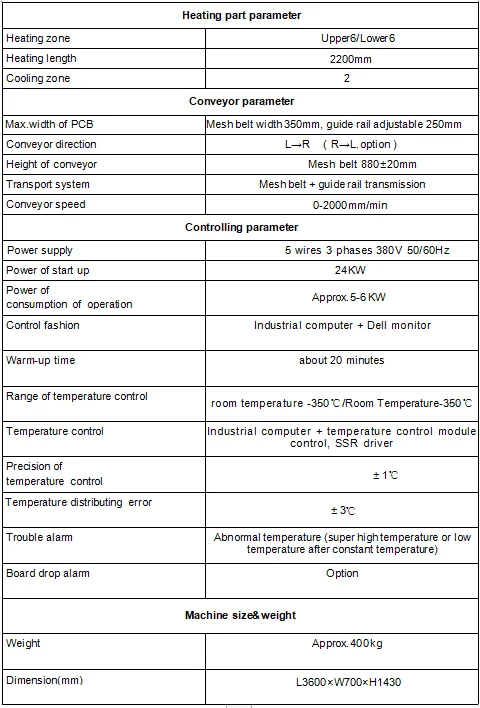

Product Parameter

|

Heating part parameter

|

|

|

Heating zone

|

Upper 6/ Lower 6

|

|

Heating length

|

2200mm

|

|

Cooling zone

|

2

|

|

Conveyor parameter

|

|

|

Max.width of PCB

|

Mesh belt width 350mm, guide rail adjustable 250mm

|

|

Conveyor direction

|

L→R ( R→L.option )

|

|

Height of conveyor

|

Mesh belt 880±20mm

|

|

Transport system

|

Mesh belt + guide rail transmission

|

|

Conveyor speed

|

0-2000mm/min

|

|

Controlling parameter

|

|

|

Power supply

|

5 wires 3 phases 380V 50/60Hz

|

|

Power of start up

|

24KW

|

|

Power of

consumption of operation |

Approx.5-6KW

|

|

Control fashion

|

Industrial computer + Dell monitor

|

|

Warm-up time

|

about 20 minutes

|

|

Range of temperature control

|

room temperature -350℃/Room Temperature-350℃

|

|

Temperature control

|

Industrial computer + temperature control module control, SSR driver

|

|

Precision of

temperature control |

± 1℃

|

|

Temperature distributing error

|

± 3℃

|

|

Trouble alarm

|

Abnormal temperature (super high temperature or low temperature after constant temperature)

|

|

Board drop alarm

|

Option

|

|

Machine size&weight

|

|

|

Weight

|

Approx.400kg

|

|

Dimension(mm)

|

L3600×W700×H1430

|

|

Heating characteristics

|

|

|

Heating ZONE number

|

up 6 down 6

|

|

Number of cooling zones

|

2

|

|

Heating time

|

Starting time from normal temperature to temperature equilibrium: about 20 minutes

|

|

heating sequence

|

Raise the temperature one by one from the middle to both sides, saving 1/3 of the energy or time

|

|

Temperature curve conversion time

|

<15min (temperature adjustment amplitude difference <100℃)

|

|

Heating zone temperature control accuracy

|

±1℃

|

|

Temperature deviation within the substrate

|

±2℃

|

|

No load → full load (or reverse) thermal balance recovery time

|

≤25 秒

|

|

Temperature zone independent shutdown function

|

Each independent temperature control zone can be turned off independently on the computer. When the air circulation and heating in

the lower temperature zone are all turned off, the maximum temperature difference can be generated on the front and back sides of the PCB. |

|

heating element

|

|

|

hot air motor

|

Imported high temperature resistant long axis motor, speed 2800rpm

|

|

Heating element

|

Specially made long-life winding heater with high thermal efficiency and sensitivity and small thermal inertia

|

|

Air duct structure

|

Efficiently accelerates the air duct to provide sufficient circulating air volume

|

|

Machine body structure

|

|

|

Rack structure

|

Overall frame welded structure, sturdy and durable

|

|

door structure

|

They are all detachable structures, providing maximum maintenance space.

|

|

Electrical appliances and control performance

|

|

|

Control host

|

Industrial computer + Siemens PLC

|

|

Control surface

|

Genuine Windows 10, free switching between Chinese and English online

|

|

Equipment and personnel safety

|

Install leakage protector

|

|

Too high or too low temperature alarm function

|

|

|

Appliance reliability

|

All imported components

|

|

Machine status record

|

Automatically records the working status of each temperature zone and each operating part of the whole machine, and the data is

saved for one year. |

|

Temperature zone temperature curve chart

|

Temperature curve files for each temperature zone are generated daily, and users can view and analyze the temperature trend of

each temperature zone. |

|

production database

|

The system can generate PCB production reports for different board numbers.

|

|

Alarm list

|

The system will save all alarms into files, and users can view the alarm items and alarm time.

|

|

Temperature curve test

|

The system has a temperature curve test function and analyzes based on the curve. (Standard configuration: 3 points)

|